2. Lead (L)

a. The distance traveled by a thread during

one complete revolution of the worm

around its axis.

b. The lead and the linear pitch are the same

on a single-start worm. On a double-start

worm, the lead is twice the linear pitch, and

on a triple-start worm, the lead is three

times the linear pitch.

c. The number of starts multiplied by the

linear pitch equals the lead.

No. of S LP = Lend

d. The lead is needed to determine the proper

gear train ratio to set the table travel on the

milling machine and to perform work on

the lathe machine.

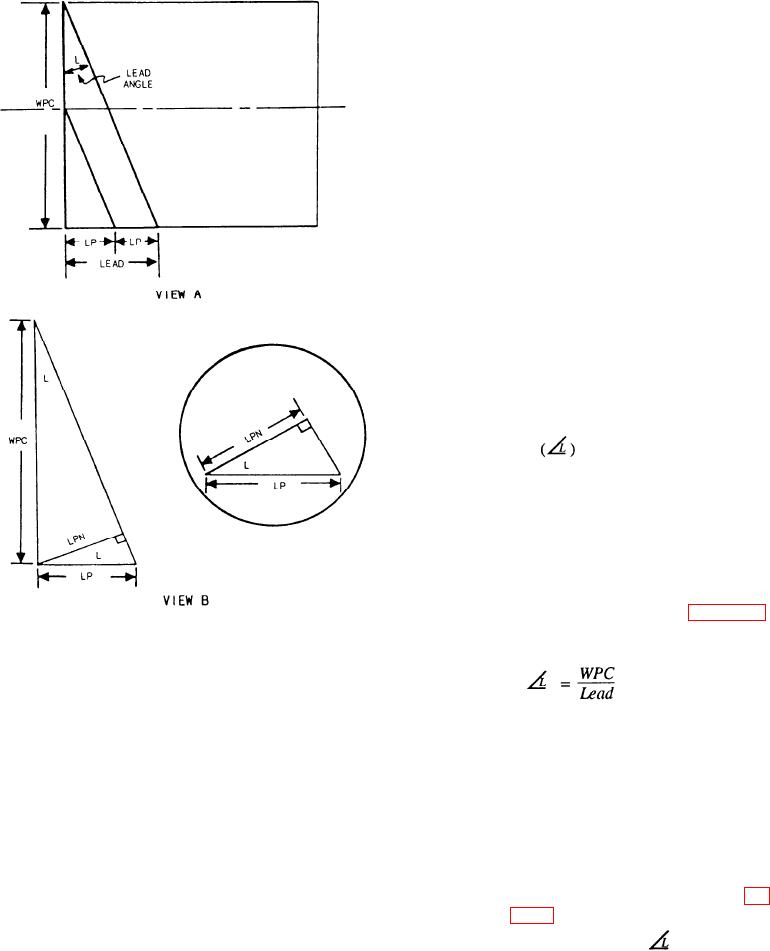

3. Lead angle

a. The angle formed by the thread and a line

drawn at a right angle to the axis of the

worm.

b. It can be found by dividing the lead into the

worm's pitch circle. The result is the

cotangent of the lead angle (fig. 14-23,

Figure 14-23.--Development of lead angle and linear pitch

view A).

(normal).

Therefore: COT

WORM AND WORM WHEEL

4. Tooth dimensions

NOMENCLATURE AND FORMULA

DEVELOPMENT

a. Linear pitch normal (LPN)

(1) Measurement of the thread (tooth) at a

You will need the following terms and formulas

right angle to its face.

when you plan and manufacture a worm and a worm

wheel:

(2) It can be found by multiplying the linear

pitch by the cosine of the lead angle (fig.

1. Linear pitch (LP)

14-23, view B).

a. The distance from a point on one thread to

LPN = LP COS

a corresponding point on the next thread.

b. This distance is measured parallel to the

(3) The tooth parts are the same in worm

and spur gears.

axis of the thread.

14-23