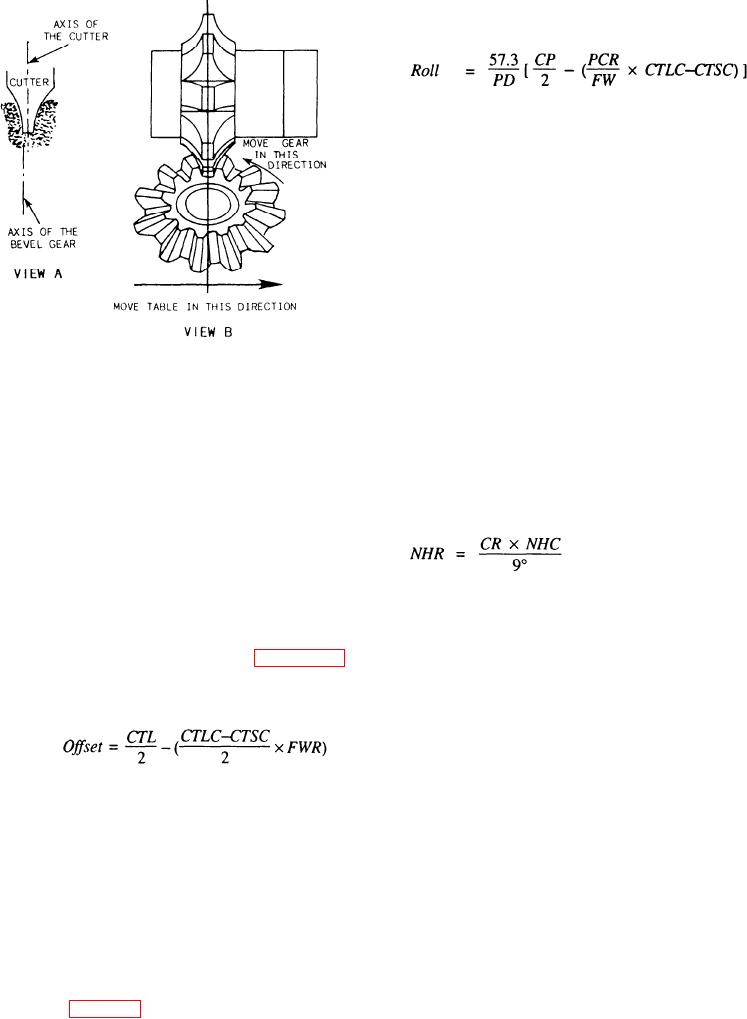

the opposite direction of the offset. Determine the

amount of roll by using the following formula:

Where:

= constant (degrees per radian)

57.3

CTLC = tooth thickness (cutter), large end

CTSC = tooth thickness (cutter), small end

CP

= circular pitch

PD

= pitch diameter

Figure 14-19.--Rolling and offsetting a bevel gear.

PCR

= pitch cord radius

FW

= width

When you prepare to cut a bevel gear, remember

that the milling machine is the only machine available

and the roll is expressed in degrees.

to you. Therefore, you must take steps like offsetting

To accomplish the roll, you must know the amount

the cutter (moving the milling machine table a

of index crank movement, which you can find with the

calculated amount) and rolling the gear blank to cut the

following formula:

correct profile on the gear tooth. The following

information will help you calculate the amount of offset

in inches and the roll of the gear blank in degrees.

Offsetting The Cutter

Where:

NHR = number of holes to roll

To offset the cutter, move it from the axis of the gear

blank a calculated distance as shown in figure 14-19,

CR

= calculated roll in degrees

view A. Use the following formula to determine the

distance:

NHC = number of hole circle to index properly

9

(express in degrees--one turn of the

index crank)

Where:

CTLC = tooth thickness, large end

Use the largest hole circle available when you select

your number of hole circles because the largest hole

CTSC = tooth thickness, small end

circle has less arc between holes.

FWR = face width ratio

After you have milled the bevel gear teeth

completely, measure the tooth thickness of the pitch line

Rolling The Gear Blank

of both the large and the small ends of the gear. These

measurements should be equal to the dimensions you

previously determined in your basic calculation. If they

After you offset the gear blank, roll it back to the

are not, check the setup and your calculations to identify

center line of the small end of the tooth by turning the

index crank (fig. 14-19, view B). The roll is always in

your errors.

14-21