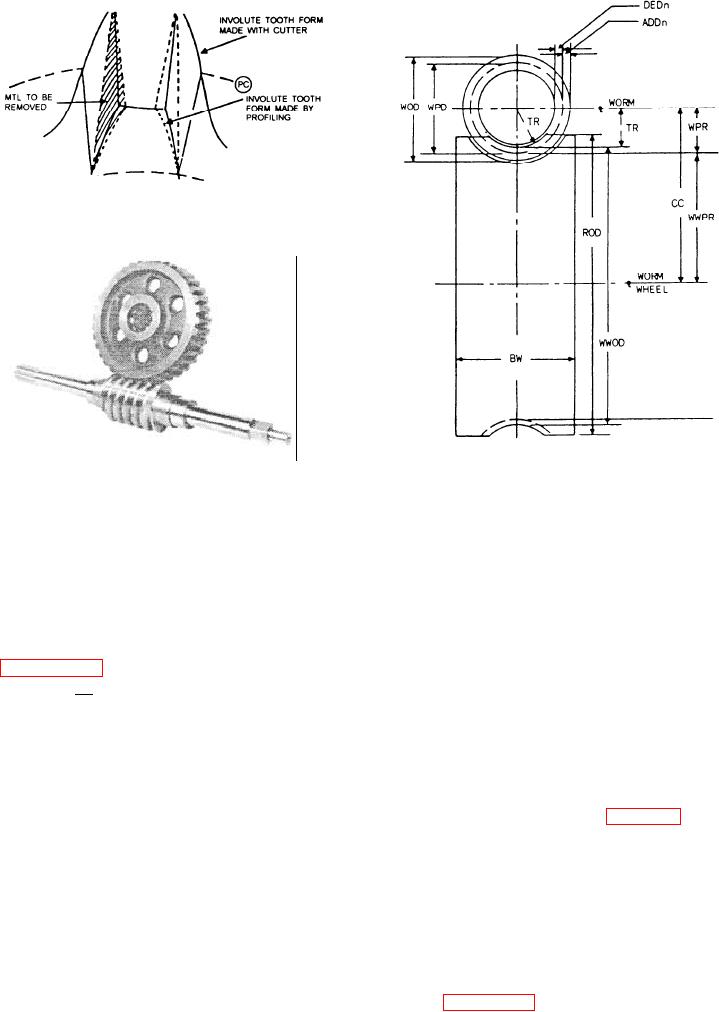

Figure 14-20.--Profiling a bevel gear.

WOD - Worm outside diameter

WPD - Worm pitch diameter

Figure 14-21.--Worm and worm gear.

DEDn - Dedendum

ADDn - Addendum

TR - Throat radius

WPR - Worm pitch radius

Remember, you cannot machine a perfect bevel

CC - Center-to-center distance

gear in a milling machine. As you learned earlier, you

ROD - Rim outside diameter

only use part of the cutter's contour when you machine

WWOD - Worm wheel outside diameter

the small end of the tooth. So, to finish the bevel gear

WWPR - Worm wheel pitch radius

teeth properly, you must file the contour as illustrated

BW - Blank width

in figure 14-20 . This is known to a Machinery

Figure 14-22.--Parts of a worm and worm gear.

Repairman as profiling the gear.

To file a tooth, start at the top of the large end of the

tooth and gradually work to the pitch line at the small

A worm, sometimes called a worm thread,

end.

resembles an Acme thread. Worms can be either solid

After you have determined that the gear is properly

or cylinder-type mounted on a shaft. Both are installed

formed, give the gear a final touch by deburring it.

perpendicular to the worm gear (fig. 14-21). Worms

may have single, double, or triple threads. One

revolution of a worm with a single thread turns the

WORMS AND WORM GEARS

circumference of the worm gear an amount equal to the

A worm gear is sometimes called a worm wheel. It

distance between identical points on two adjacent teeth,

has teeth cut at an angle to the axis of rotation and

or one circular pitch, and so on.

radially in the gear face. The teeth are helical and

This type of gearing is also known as an "endless

conform to the helix angle of the teeth on the worm.

screw," where the worm is the driver and the worm gear

Worm gears are used for heavy-duty work where a

is driven. Figure 14-22 identifies the parts of a worm

large reduction of speed is required. They are used

and a worm wheel.

extensively in speed reducers.

14-22