bevel gear calculations. Simply substitute the constant

into the following formula:

NOTE: Obtain the constant from table 14-3, part

B.

The procedure used to solve the chordal thickness

of the large tooth of a bevel gear is the same as that for

a spur gear.

To determine the chordal addendum (corrected

addendum) ac small and the chordal thickness of the

small tooth, multiply the value of the large tooth by the

proportional tooth factor (PTF).

Backlash Allowance of a Bevel Gear

You learned earlier that backlash is the amount by

which the width of a gear tooth space, when two gears

are meshed together, exceeds the thickness of the

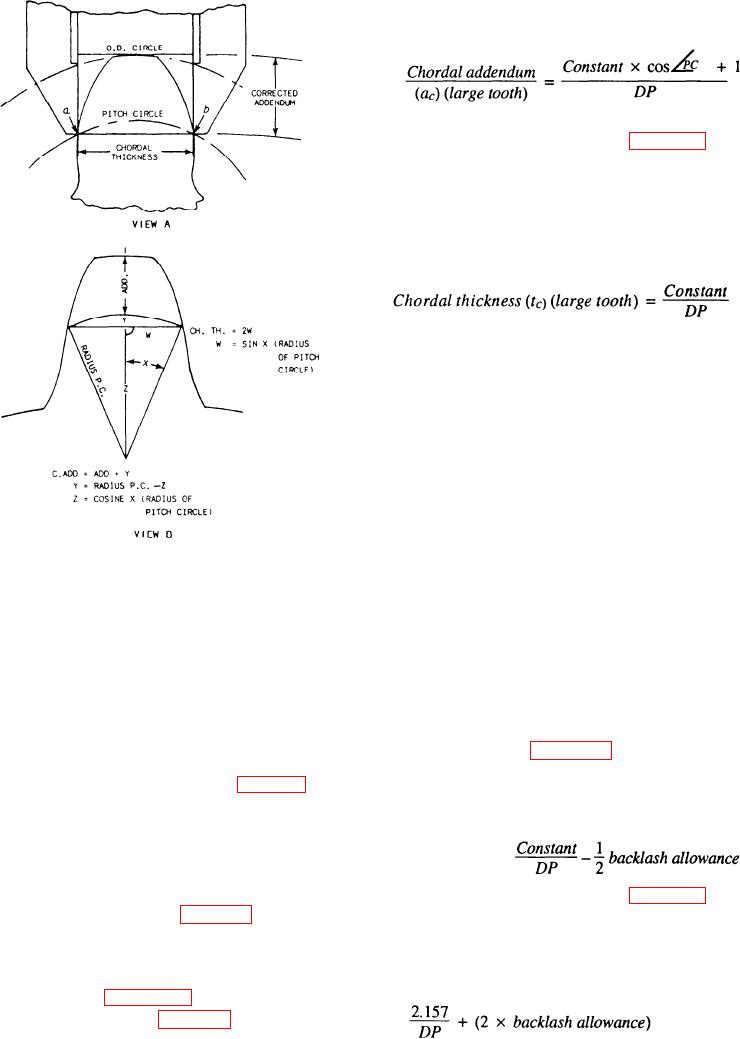

Figure 14-17.--Formulas for calculating chordal thickness.

engaging tooth on the pitch circles. You must take these

measurements with a device used for that purpose.

Theoretically, when gear teeth are meshed, they

Chordal Addendum and Chordal Thickness

should run with little backlash. However, manu-

facturing tolerances make this impossible. There must

Before you can measure a manufactured gear tooth

be space between the gear teeth for lubrication and for

accurately, you must know the chordal addendum and

expansion due to temperature changes at high speeds.

the chordal thickness. These dimensions are used to

Just as with helical gears, bevel gears must have

measure the size of the gear tooth.

enough freedom between teeth so they will not bind

Chordal addendum (corrected addendum) a c. This

when the gears turn. Table 14-3, part B shows the

is the distance from the top of a gear tooth to the chord

recommended backlash allowance corresponding to the

across the gear tooth at the pitch circle (fig. 14-17, view

gear's diametral pitch (DP).

A). It is the point at which the chordal thickness is

To determine the chordal thickness with backlash

at the large end of the tooth, use the following formula:

measured.

Chordal thickness of a gear tooth (tc). This is the

Chordal thickness =

distance in a straight line (chord) from one side of the

tooth to the other side at the points where the pitch circle

NOTE: Obtain the constant from table 14-3, part

passes through the gear tooth (fig. 14-17, view A).

B.

Use the following methods to calculate the chordal

To determine the corrected working depth (WD)

addendum and the chordal thickness:

with backlash at the large end of the tooth, use the

You can calculate the dimensions by using the

following formula:

formulas shown in figure 14-17, view B. However, you

can also use tables such as table 14-3, part B, to make

14-19