straight but the sides are tapered. The center line of the

teeth will intersect at a given point.

Bevel gears are usually manufactured on gear-

cutting machines. However, you will occasionally have

to make one on a universal milling machine.

This section of the chapter deals with the angle

nomenclature of a bevel gear as well as the development

of the triangles needed to manufacture one.

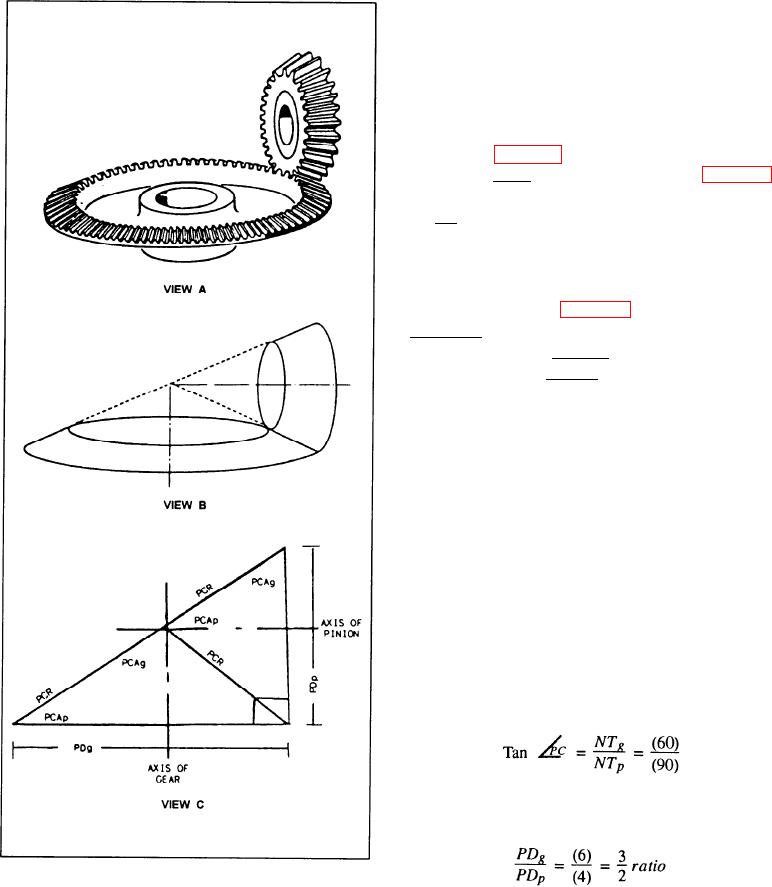

When two bevel gears whose shaft angles equal 90

are in mesh (fig. 14-14, view A) they form a triangle. It

is called the mating gear triangle. The cones (fig. 14-14,

view B) that form the basis of the bevel gears are called

the pitch cones. These cones are not visible at all on the

finished gear, but they are important elements in bevel

gear design.

The angle that is formed at the lower left-hand

corner of the triangle (fig. 14-14, view C) is called the

pitch cone angle of the pinion. The altitude of the

triangle is called the pitch diameter of the pinion, and

its base is called the pitch diameter of the gear.

The hypotenuse of the triangle is twice the pitch

cone radius.

The pitch diameter (gear and pinion), the number

of teeth (gear and pinion), and the actual ratio between

the gear and the pinion are all in ratio. Therefore, we

can use any of these three sets to find the pitch cone

angle (PCA).

Example: A 10 diametral pitch (DP) gear with 60

teeth has a pitch diameter (PD) of 6 and a 10 DP pinion

with 40 teeth has a PD of 4. Therefore, the ratio of the

gear and the pinion is 3:2.

We can determine the PCA by simply substituting

the known values into the formula:

or

Figure 14-14.--Development of the mating gear triangle.

NOTE: The pitch cone angle of the pinion (PCA p)

is the compliment of the pitch cone angle of the gear

(PCAg).

14-15