machine table must move to rotate the spindle of the

dividing head one revolution. Most milling machines

have a table screw of 4 threads per inch with a lead of

or

0.250 inch (1/4 inch) and a dividing head (index head)

with a 40:1 worm-to-spindle ratio. When the index head

is connected to the table through a 1:1 ratio, it will cut

a lead of 10 inches. Thus, 40 turns of the lead screw are

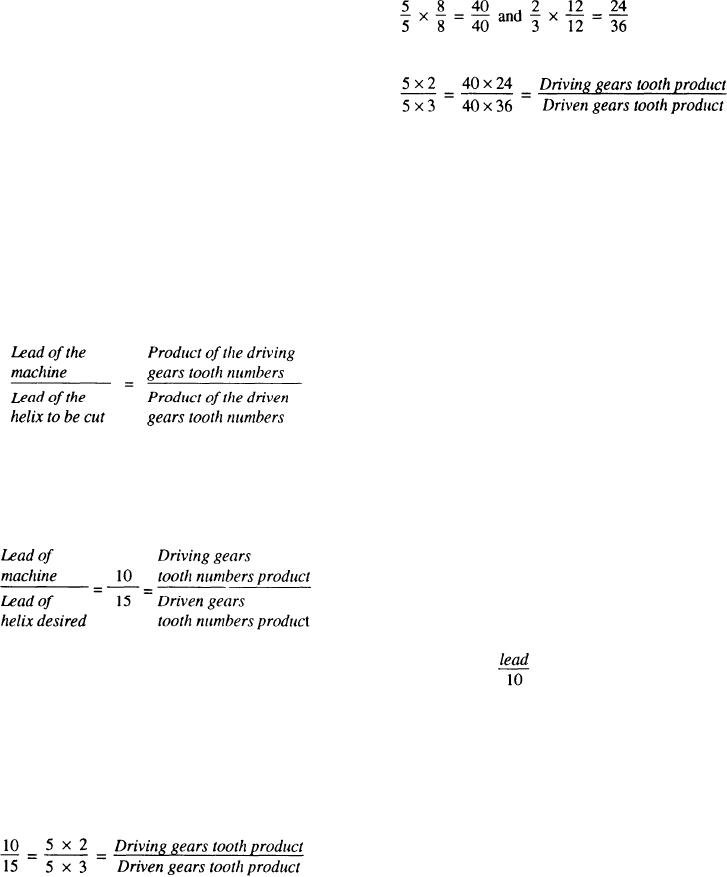

Thus, gears with 40 and 24 teeth become the driving

required to make the spindle revolve one complete

gears, and gears with 40 and 36 teeth become the driven

revolution (40 0.250 inch = 10 inches). Therefore,

gears.

10 will be the constant in our gear train ratio formula,

These gears would be arranged in the gear train as

follows:

Gear A (on the dividing-head worm shaft)

All ratios other than 1:1 require modification of the gear

40 teeth (driven)

train.

Gear B (first gear on the idler stud)

From this formula, we can also say that the

24 teeth (driving)

Gear C (second gear on the idler stud)

36 teeth (driven)

Gear D (gear on the table screw)

40 teeth (driving)

Example:

The positions of the driving gears may be

Determine the change gears required for a lead of

interchanged without changing their products. The

15 inches. Assume the milling machine has a lead of 10

same is true of the driven gears. Thus, several different

inches.

combinations of driving and driven gears will produce

a helix with the same lead.

Before you start to figure your change gear, check

your office library for a ready-made table for the

selection of gears devised by the Cincinnati Milling

Machine Company. These gears have been determined

If you could use a simple gear train (one driving and

using the formula,

. If you have already calculated

one driven gear), a lo-tooth gear on the table screw

meshed with a 15-tooth gear on the dividing-head worm

your lead, match it with the lead in the table and select

shaft would produce the 15-inch lead required.

the gears for that lead.

However, gears of 10 and 15 teeth are not available, and

the drive system is designed for a compound gear train

MANUFACTURING A HELICAL GEAR

of four gears. Therefore, the fraction 10/15 must be split

into two fractions whose product equals 10/15. Do this

by factoring as follows:

At this point of the chapter, you are ready to

manufacture a helical gear. In a case where you must

manufacture a helical gear from a sample, you should

do the following:

If gears with 5 and 2 teeth were possible, they would

1. Find the DP.

be the driving gears, and gears with 5 and 3 teeth would

2. Measure the OD. This is also the ROD.

be the driven gears. But since this is not possible, each

of the fractions must be expanded by multiplying both

3. Find the ADD.

the numerator and the denominator by a number that

4. Find the RPD.

will result in a product that corresponds to the number

of teeth on available gears:

5. Find the NT.

14-13