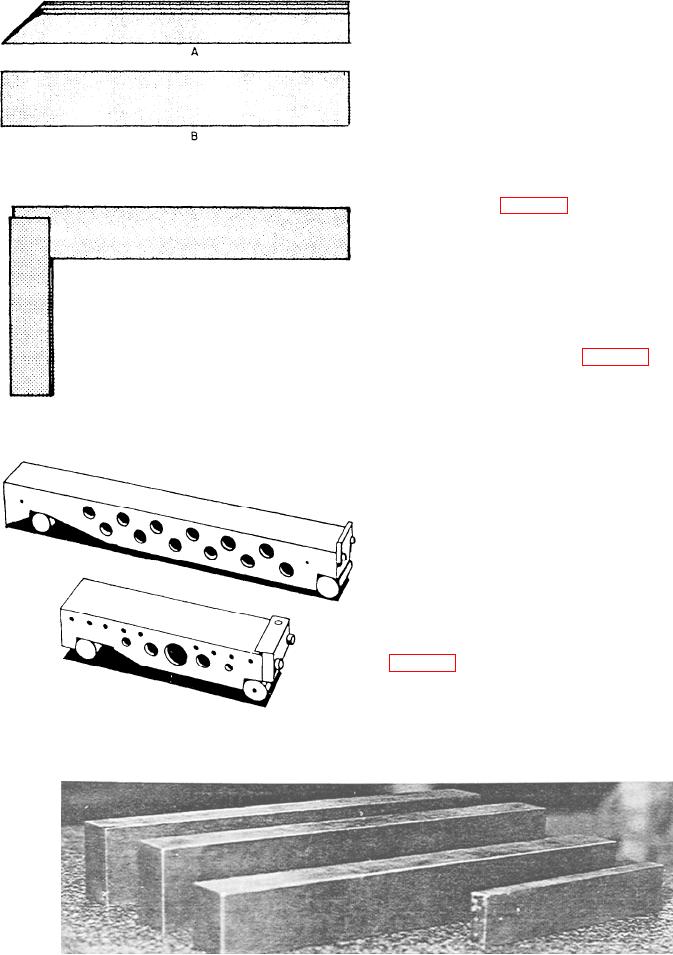

Always keep a straightedge in a box when it is not

in use. Some straightedges are marked with two arrows,

one near each end, which indicate balance points. When

a box is not provided, place resting pads on a flat surface

in a storage area where no damage to the straightedge

will occur from other tools. Then, place the straightedge

so the two balance points sit on the resting pads.

MACHINIST'S SQUARE.--The most common

Figure 1-23.--Straightedge.

type of machinist's square has a hardened steel blade

securely attached to a beam. The steel blade is NOT

graduated. (See fig. 1-24.) This instrument is very

useful in checking right angles and in setting up work

The size of machinist's squares ranges from 1 1/2 to

36 inches in blade length. You should take the same

care of machinist's squares, in storage and use, as you

do with a micrometer.

SINE BAR.--A sine bar (fig. 1-25) is a precision

tool used to establish angles that require extremely close

accuracy. When used in conjunction with a surface

plate and gauge blocks, angles are accurate to 1 minute

Figure 1-24.--Machinist's square.

(1/60). The sine bar is used to measure angles on work

and to lay out an angle on work to be machined, or work

may be mounted directly to the sine bar for machining.

The cylindrical rolls and the parallel bar, which make up

the sine bar, are all precision ground and accurately

positioned to permit such close measurements. Be sure

to repair any scratches, nicks, or other damage before

you use the sine bar, and take care in using and storing

the sine bar. Instructions on using the sine bar are

included in chapter 2.

PARALLEL BLOCKS.--Parallel blocks

(fig. 1-26) are hardened, ground steel bars that are

used to lay out work or set up work for machining.

The surfaces of the parallel block are all either

parallel or perpendicular, as appropriate, and can be

used to position work in a variety of setups with

Figure 1-25.--Sine bars.

28.319

Figure 1-26.--Parallel blocks.

1-19