meanings of these terms and the importance of

observing the distinction between them.

TOLERANCE

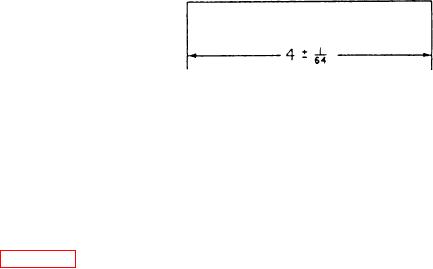

Figure 2-1.--Basic dimension and tolerance.

In most instances it's impractical and unnecessary

to work to the absolute or exact basic dimension. The

designer calculates, in addition to the basic

interference allowance of 0.001 inch. As the shaft is

dimensions, an allowable variation. The amount of

larger than the hole, force is necessary to assemble the

variation, or limit of error permissible, is indicated on

parts.

the drawing as plus or minus (+) a given amount, such

as 0.005 or 1/64. The difference between the

What is the relationship between tolerance and

allowable minimum and the allowance maximum

allowance? When you manufacture mating parts, you

dimension is tolerance. For example, in figure 2-1:

must control the tolerance of each part so the parts

will have the proper allowance when they are

Basic dimension = 4

assembled. Here's an example. A hole 0.250 inch in

Long limit = 4 1/64

diameter with a tolerance of 0.005 inch (0.0025) is

Short limit = 3 63/64

prescribed for a job. The shaft to be fitted in the hole

is to have a clearance allowance of 0.001 inch. You

Tolerance = 1/32

must finish the hole within the limits and determine

When tolerances are not actually specified on a

the required size of the shaft exactly before you can

drawing, you can make fairly concrete assumptions

make the shaft. If you finish the hole to the upper

concerning the accuracy expected, by using the

limit of the basic dimension (0.2525 inch), you would

following principles. For dimensions that end in a

machine the shaft to 0.2515 inch or 0.001 inch smaller

fraction of an inch, such as 1/8, 1/16, 1/32, 1/64, the

than the hole. If the dimension of the shaft was given

expected accuracy is 1/64 inch. When the

with the same tolerance as the hole there would be no

control over the allowance between the parts. As

dimension is given in decimal form, the following

much as 0.005-inch allowance (either clearance or

applies:

interference) could result.

If a dimension is given as 3.000 inches, the

accuracy expected is 0.0005 inch; or if the

To retain the required allowance and still permit

dimension is given as 3.00 inches, the accuracy

some tolerance in the dimensions of the mating parts,

expected is 0.005 inch. The +0.0005 is called in

the tolerance is limited to one direction on each part.

shop terms, "plus or minus five ten-thousandths of an

This single direction (unilateral) tolerance stems from

inch." The 0.005 is called "plus or minus five

the basic hole system. If a clearance allowance is

thousandths of an inch."

required between mating parts, the hole may be larger

but not smaller than the basic dimension; the part that

ALLOWANCE

fits into the opening may be smaller but not larger

than the basic dimension. Thus, shafts and other parts

Allowance is an intentional difference planned in

that fit into a mating opening have a minus tolerance

dimensions of mating parts to provide the desired fit.

only, while the openings have a plus tolerance only. If

A CLEARANCE ALLOWANCE permits movement

an interference allowance between the mating parts is

between mating parts when they are assembled. For

required, the situation is reversed; the opening can be

example, when a hole with a 0.250-inch diameter is

smaller but not larger than the basic dimension, while

fitted with a shaft that has a 0.245-inch diameter, the

the shaft can be larger but not smaller than the basic

clearance allowance is 0.005 inch. An INTER-

dimension. Therefore, you can expect to see a

FERENCE ALLOWANCE is the opposite of a

tolerance such as +0.005, -0, or +0, -0.005, but with

clearance allowance. The difference in dimensions in

the required value not necessarily 0.005. You can get

this case provides a tight lit. You would need force to

a better understanding of a clearance allowance, or an

assemble parts that have an interference allowance. If

interference allowance, if you make a rough sketch of

a shaft with a 0.251-inch diameter is fitted into the

the piece and add dimensions to the sketch where they

hole identified in the preceding example, the

difference between the dimensions will give an

apply.

2-2