basic check (view E, fig. 2-3). The NOTES block of

number is shown for roughness height, it is the

the drawing will show any further surface finish

maximum permissible roughness height rating; if two

requirements, such as waviness width or height.

are shown, the top number is the maximum (view B,

fig. 2-3). A point to remember is that the smaller the

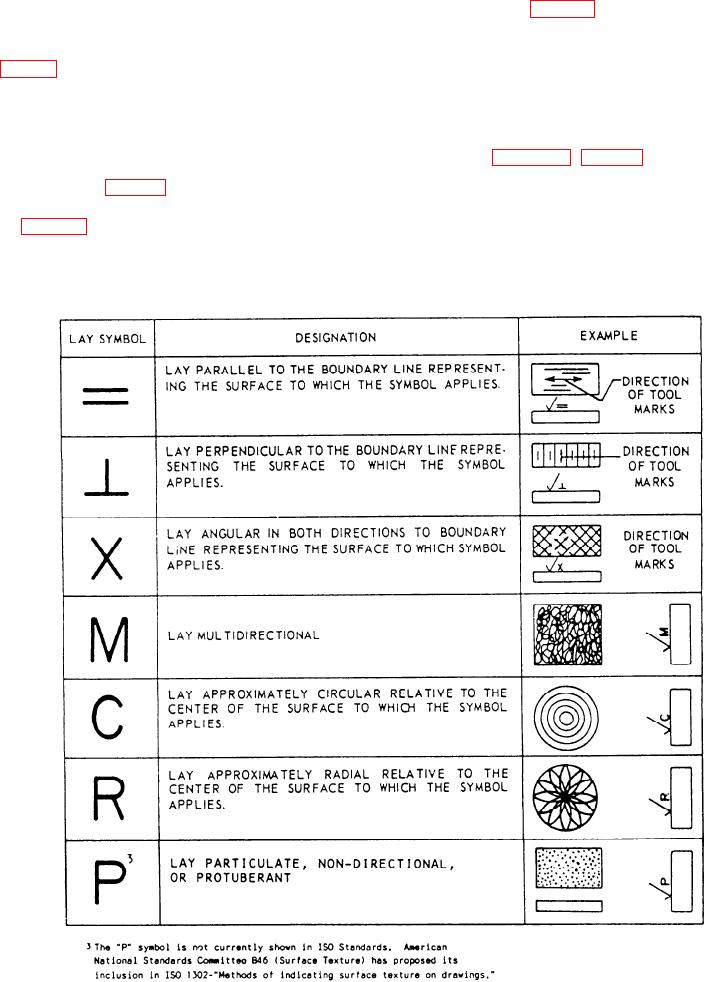

Lay is the direction of the predominant surface

number in the roughness height rating, the smoother

pattern produced by the tool marks. The symbol

the surface.

indicating lay is placed to the right and slightly above

the point of the surface roughness symbol, as shown

Waviness height values are shown directly above

in view F of figure 2-3. (Fig. 2-4 shows the seven

the extension line at the top of the long leg of the basic

symbols that indicate the direction of lay.)

check (view C, fig. 2-3). Waviness width values are

placed to the right of the waviness height values (view

The roughness width value is shown to the right

D, fig. 2-3). Where minimum requirements for

of and parallel to the lay symbol. The roughness

contact or bearing surfaces must be shown, the

width cutoff is placed immediately below the

extension line and to the right of the long leg of the

percentage is placed at the top of the long leg of the

Figure 2-4.--Symbols indicating the direction of lay.

2-4