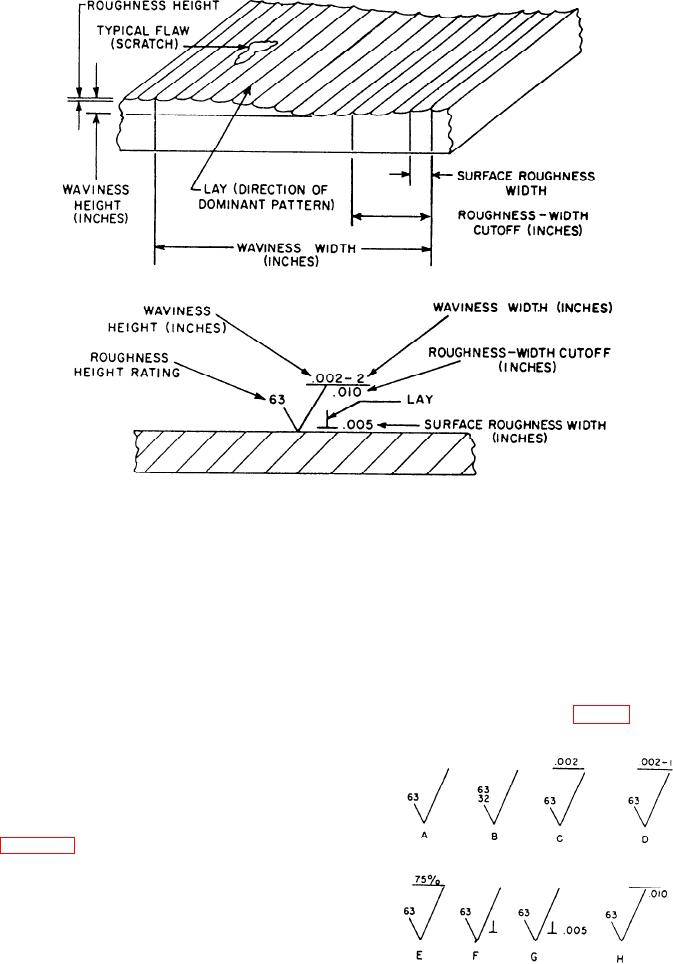

Figure 2-2.--Relation of symbols to surface characteristics.

SURFACE CHARACTERISTICS OF

roughness symbol that you'll find on the drawing is a

METAL

check mark. This symbol is supplemented with a

horizontal extension line above it when requirements

While you must control the finished dimensions

such as waviness width or contact area must be

of a part, you also must consider the degree of

specified in the symbol. A drawing that shows only

smoothness, or surface roughness. Both are very

the basic symbol indicates that the surface finish

important in the efficiency and life of a machine part.

requirements are detailed in the NOTES block. The

A finished surface may appear to be perfectly flat;

roughness height rating is placed at the top of the

but, when you examine it with surface finish measuring

short leg of the check (view A, fig. 2-3). If only one

instruments, you will find it is formed of irregular

waves. On top of these waves are other smaller waves

that we'll call peaks and valleys. You'll measure these

peaks and valleys to determine the surface roughness

measurements of height and width. Measure the larger

waves to give the waviness height and width measure-

ments. Figure 2-2 illustrates the general location of the

various areas for surface finish measurements and the

relation of the symbols to the surface characteristics.

Surface roughness is the measurement of the

finely spaced surface irregularities; their height,

width, direction, and shape establish the predominant

surface pattern. The irregularities are caused by the

cutting or abrading action of the machine tools that

Figure 2-3.--Symbols used to indicate surface roughness,

have been used to obtain the surface. The basic

waviness, and lay.

2-3