Figure 2-11.--Checking surface finish on the machine.

check the workpiece manually while it is in the

machine (fig. 2-11).

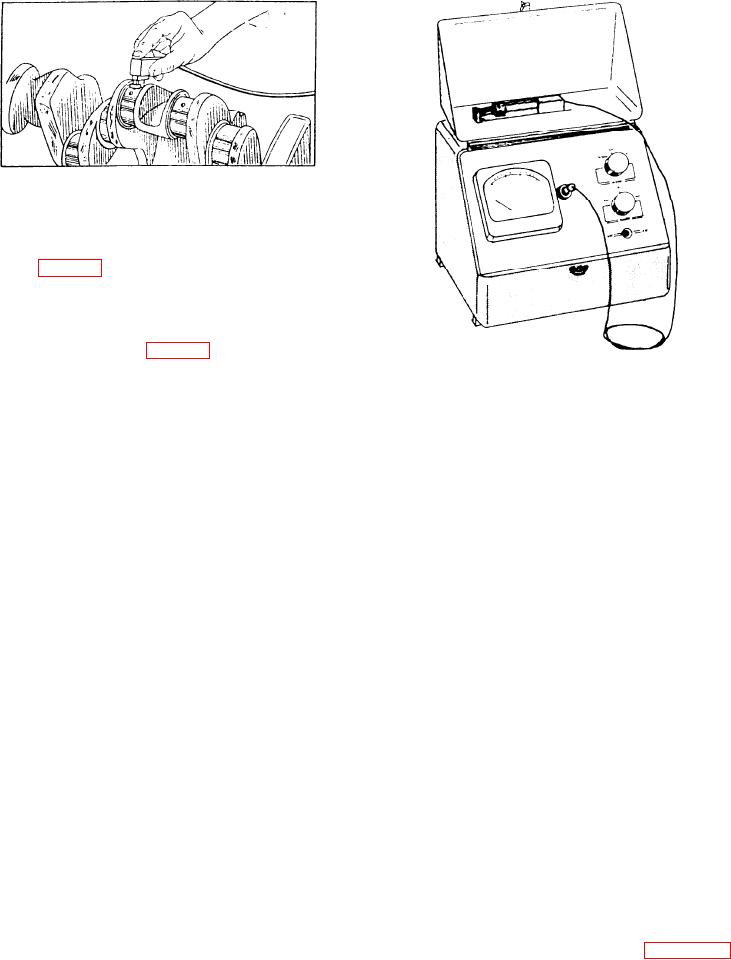

SURFACE ANALYZER

The surface analyzer (fig. 2-12) is a practical shop

instrument designed for the accurate measurement of

Figure 2-12.--Surface analyzer.

surface finish roughness. Like the profilometer, it

measures the irregularities of the surface finish and

relationship of the surfaces. That understanding will

records them in microinches. This is done by a tracer

help you plan the sequence of machining operations.

stylus, which registers the rise and fall of the peaks

and valleys on the finished surfaces. These variations

Mechanical drawing and layout are closely

are amplified and indicated on the electrical meter,

related subjects; knowledge of one will help you

calibrated to read in microinches.

understand the other. You also must know general

mathematics, trigonometry, and geometry, and how to

select and use tools for jobs related to layout and

LAYOUT METHODS

mechanical drawing. Study Mathematics, Volume I,

Layout is the term used to describe the marking of

NAVEDTRA 10069-D1; Mathematics, Volume 2-A,

metal surfaces to provide an outline for machining. A

NAVEDTRA 10062; Use and Care of Hand Tools and

layout is comparable to a single view (end, top, or

Measuring Tools, NAVEDTRA 12085, and Blueprint

side) of a part that is sketched directly on the

Reading and Sketching, NAVEDTRA 10077-F7, for

workpiece. The degree of difficulty depends on the

additional information.

intricacies of the part to be laid out and the number of

The following information applies to practically

operations required to make the part. A flange layout,

all layouts. Layout lines are formed by using a

for example, is relatively simple as the entire layout

reference edge or point on the stock or by using the

can be made on one surface of the blank flange.

surface plate as a base. Study carefully the section on

However, an intricate casting may require layout lines

geometric construction. It will help you make layouts

on more than one surface. This requires careful study

when you can't use a reference edge of the stock or a

and concentration to make sure the layout will have

surface plate mounting of the stock.

the same relationships as those shown on the drawing

(or sample) that you are using.

LINES SQUARE OR PARALLEL TO

When a part must be laid out on two or more

EDGES

surfaces, you may need to lay out one surface and

machine it to size before using further layout lines.

When scribing layout lines on sheet metal, hold

This prevents removal of layout lines on one surface

the scratch awl, or scribe, as shown in figure 2-13.

while you are machining another.

Lean it toward the direction in which it will be moved

and away from the straightedge. This will help you

The process of computing and transferring

scribe a smooth line that will follow the edge of the

dimensions will help you become familiar with the

2-8