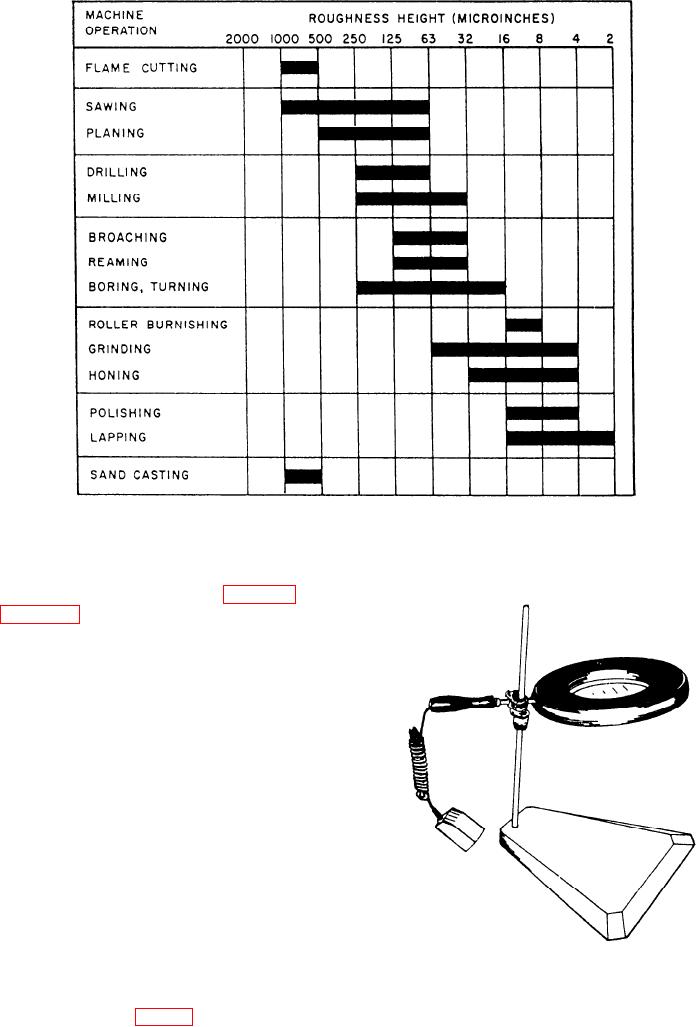

Figure 2-5.--Roughness height values for machine operations.

basic check mark. These symbols for roughness

width are shown in view G and H of figure 2-3.

Figure 2-5 shows a sampling of some roughness

height values that can be obtained by the different

machine operations.

READING SURFACE FINISH QUALITY

A surface finish is seldom flat. We said earlier that

close examination with surface finish measuring

instruments shows the surface to be formed of irregular

waves. On top of the waves are other smaller

irregularities known as peaks and valleys. We will now

discuss several ways to evaluate surface finish.

VISUAL INSPECTION

There are occasions when visual comparison with

the naked eye will show that one surface is rougher

than the other. This is possible only in cases of widely

differing surfaces. You also can use visual inspection

Figure 2-6.--Magnifier with illuminator for surface inspection.

to detect large cracks in metal.

You can make a visual comparison with

illuminated magnifiers (fig. 2-6).

2-5