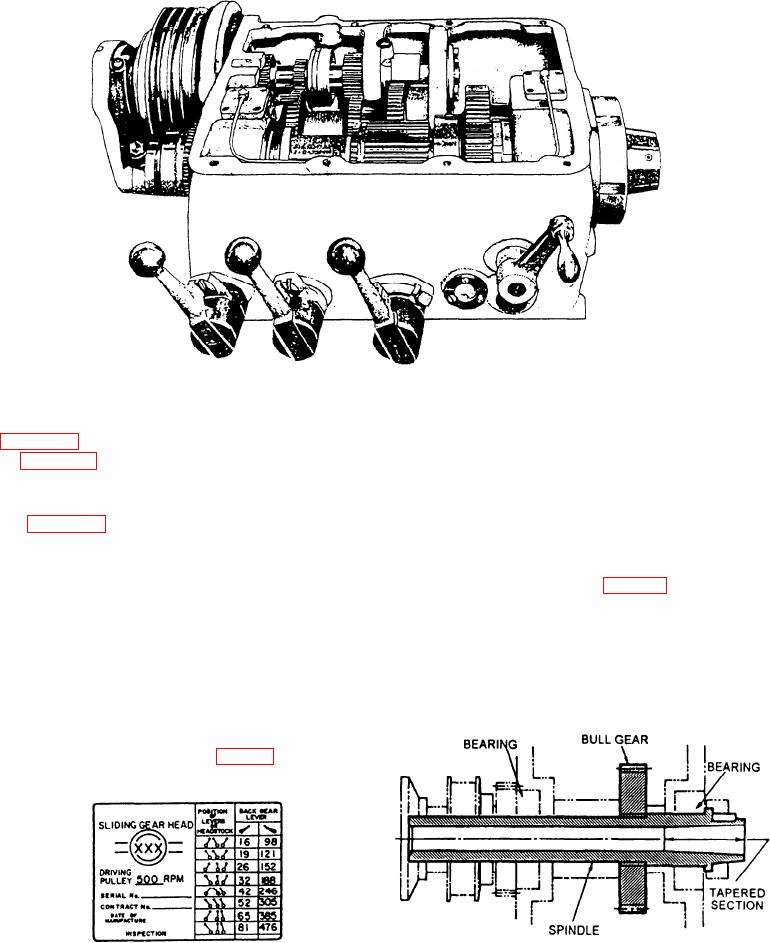

Figure 6-3.--Sliding gear-type headstock

Figure 6-4 shows this plate for the geared headstock

The headstock casing is filled with oil to lubricate

the gears and the shifting mechanism it contains.

in figure 6-3. Always stop the lathe when you shift

Parts not immersed in the oil are lubricated by either

gears to avoid damaging the gear teeth.

the splash produced by the revolving gears or by an

oil pump. Be sure to keep the oil to the oil level

Figure 6-3 shows the interior of a typical geared

indicated on the oil gauge.

headstock that has 16 different spindle speeds. The

driving pulley at the left is driven at a constant speed

by a motor located under the headstock. Various

The headstock spindle (fig. 6-5) is the main

combinations of gears in the headstock transmit the

rotating element of the lathe and is directly connected

power from the drive shaft to the spindle through an

to the work, which revolves with it. The spindle is

intermediate shaft. Use the speed-change levers to

supported in bearings at each end of the headstock

shift the sliding gears on the drive and intermediate

through which it projects. The section of the spindle

shafts to line up the gears in different combinations.

This produces the gear ratios you need to obtain the

various spindle speeds. Note that the back gear lever

has high and low speed positions for each

combination of the other gears (fig. 6-4).

Figure 6-5.--Cross section of a headstock spindle.

Figure 6-4.--Speed index plate.

6-4