There must be lip clearance behind the entire

length of the cutting edge lip that extends from the

margin of the drill to the chisel edge. This means that

there must be "relief' behind the cutting lip along its

entire length.

W h e n you grind lip clearance, use the

lip-clearance angle and the chisel-edge angle (shown

in figs. 5-30, view C and 5-31, view C) as your guide

to the amount of clearance you have ground into the

drill behind the cutting lip along its entire length. The

greater these angles are, the more clearance there will

be behind their respective ends of the cutting lip. Too

much lip clearance occurs when both the lip-clearance

angle and the chisel-edge angle exceed their top

limits. This weakens the cutting edge or lip by

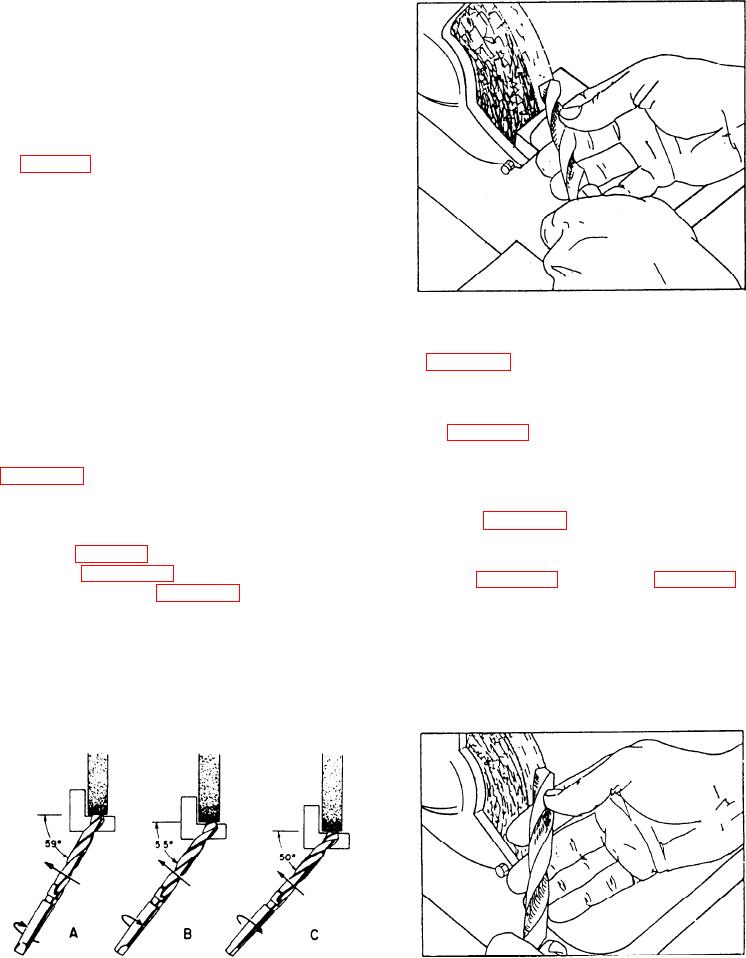

Figure 5-35.--Grinding a twist drill with a grinder (initial

removing too much metal directly behind it. Too little

position.

or no lip clearance prevents the cutting edge from

producing a chip, and the drill bit will not drill a hole.

Figure 5-34 shows the motion to the left in three

views as the angle between the face of the wheel and

To sharpen a twist drill, first ensure the grinder is

the drill decreases from about 59 to about 50.

ready. If necessary, dress the face of the wheel and

In figure 5-34, the rotation arrows in views A, B,

adjust the toolrest. Start the grinder, let it come up to

and C show the clockwise motion. The change in the

speed, and begin. Hold the twist drill as shown in

position of the cutting lip and tang also shows

figure 5-34, view A, which is a top view of the first

rotation.

step in grinding a drill. In the first step, be sure the

axis of the drill makes an angle of about 59 (half of

Because figure 5-34 is a top view, the downward

the drill-point angle) with the face of the wheel as

motion is not noticeable. However all three motions

shown in fig. 5-34, view A. Hold the cutting lip

are apparent when you compare the final position of

horizontal. Figure 5-35 is a side view of the same

the drill in figure 5-36 to the view in figure 5-35. All

drill position shown in figure 5-34, view A.

three motions taking place at the same time combine

to produce the requirements mentioned earlier in this

The actual grinding of the drill point consists of

section: (1) equal and correctly sized drill-point

three definite motions of the shank of the drill while

angles, (2) equal-length cutting lengths, (3) correct

you hold the point lightly against the rotating wheel.

clearance behind the cutting lips, and (4) correct

These three motions are (1) to the left, (2) clockwise

rotation, and (3) downward.

Figure 5-34.--Three steps for grinding a twist drill with a

Figure 5-36.--Grinding a twist drill with a grinder (final

grinder.

position.

5-22