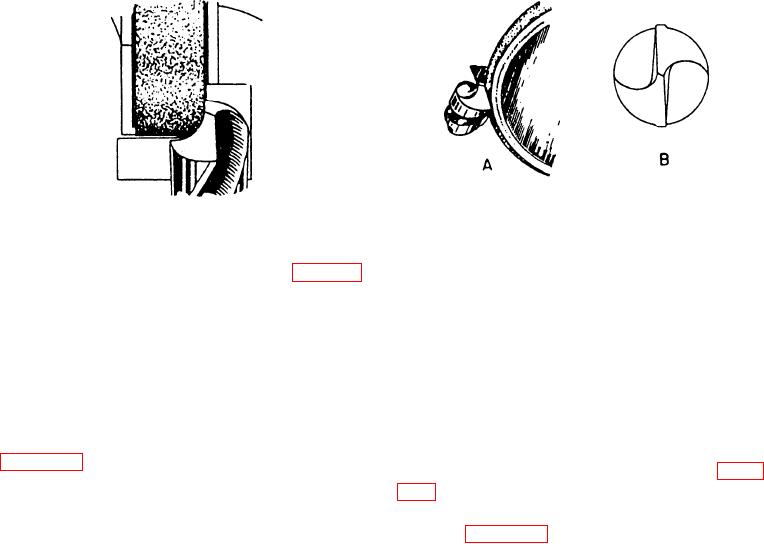

Figure 5-38.--Thinning the web of a twist drill.

Figure 5-37.--Grinding a twist drill for brass.

chisel-edge angle. Use a drill-point gauge (fig. 5-33)

THINNING THE WEB OF A TWIST

and inspection to be sure you have met these four

DRILL

requirements.

SHARPENING A TWIST DRILL TO

Repeated sharpening shortens a drill and that

DRILL BRASS

increases the web thickness at the point. This may

require web thinning.

To sharpen a drill to drill brass, hold the cutting

lip against the right side of the wheel as shown in

To thin the web of a drill, hold the drill lightly to

figure 5-37. Grind the flute slightly flat, in line with

the face of a round-faced wheel, as shown in figure

the axis of the drill, to greatly reduce the included

5-38, view A, and thin the web for a short distance

angle of the cutting lip. This will give the drill the

behind the cutting lip and into the flutes. This is

scraping action needed for brass rather than the

shown in figure 5-38, view B. Notice that the cutting

cutting action used for steel. It will prevent the

lip is actually (but only slightly) ground back,

tendency of the drill bit to be sucked into the hole

reducing its included angle a small amount but not

being drilled. This can be especially troublesome

enough to affect the operation of the drill.

when you drill through a pilot hole.

5-23