TM 55-2815-574-24

0074

FIT AND MEASURE THE PISTON RINGS AND THE PISTON

1.

Fit the new piston rings.

a.

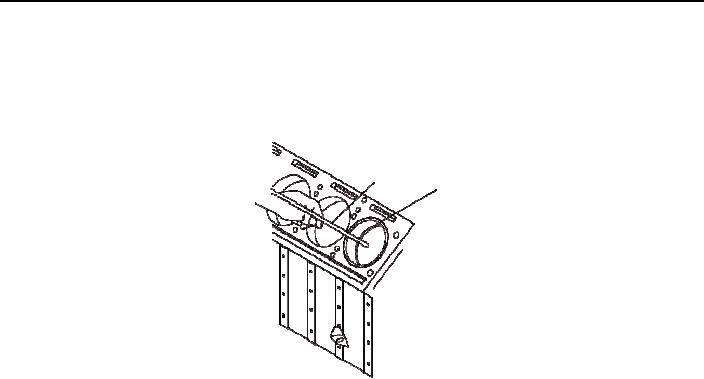

Insert one of the rings (3 or 5) at a time into the cylinder liner (2) far enough down to be within normal

ring travel.

FEELER

GUAGE

3

5

b.

Using the skirt of the piston (1), push the ring down slightly to level the ring with the top of the liner.

c.

Measure the gap between the ends of the ring as follows:

{1} Measure the new top ring (5), it should have an end gap of no less than 0.0250 in. (0.0635 cm) and not

more than 0.0450 in. (0.1143 cm).

{2} Measure the new middle and lower rings (5), they should have an end gap not less than 0.0250 in.

(0.0635 cm) and not more than 0.0450 in. (0.1143 cm).

{3} Measure the new top rings (3), they should have an end gap of no less than 0.0070 in. (0.01778 cm) and

not more than 0.0170 in. (0.004318 cm).

{4} Measure the new lower rings (3), they should have an end gap not less than 0.0100 in. (0.0254 cm) and

not more than 0.0250 in. (0.0635 cm).

CAUTION

Filing of the ring gap must only go from outside to inside to prevent chipping of the

chrome molly plate on the rings. Failure to comply will result in damage to equipment.

NOTE

The ends of the ring must remain square and the chamfer on the outer edge must be

approximately 0.015 in. (0.00381 cm).

d. If the ring gap is too small, file the ends of the ring so the ring must remain at a 90 angle to the cylinder wall.

e.

If the ring gap is to large, measure the cylinder liner, if the liner is with in tolerances, replace the ring. If the

liner is not within tolerances replace the liner and remeasure the ring gap.

f.

Using the same procedure, measure the end gap on all the rings.

0074-11