TM 55-2815-574-24

0074

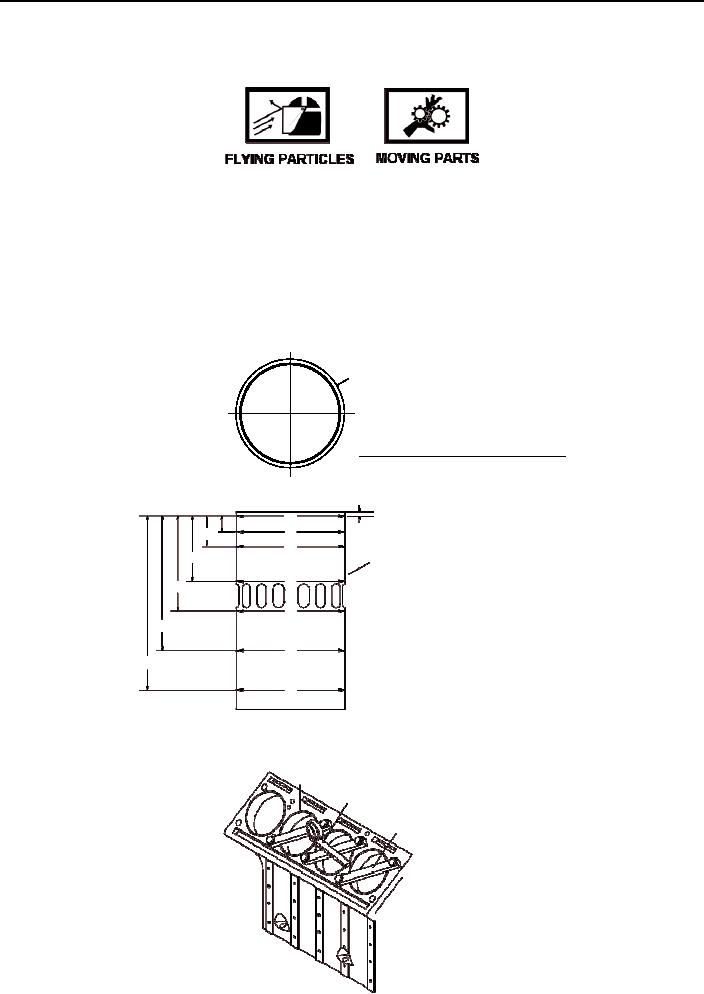

HONE THE CYLINDER LINER Continued

WARNING

Keep hands, fingers and clothing away from moving parts.

Wear protective goggles. Failure to comply may result in personnel injury.

2. Work body, cylinder hone with stones, abrasive, cylinder hone up and down the full length of the liner (2) at

300 to 400 RPM's.

NOTE

Upon completion of the honing the cylinder liner should have a criss-cross pattern of marks at

a 45 axis.

3.

Measure the cylinder liners (2) using a gage, cylinder, setting master, dial bore gage and master ring gage.

2

X

X - LONGITUDUNAL AXIS

(LENGTHWISE OF ENGINE)

Y - TRANSVERSE AXIS

(CROSSWISE OF ENGINE)

Y

A

1"

3/16 "

B

1 3/4 "

C

2

3 1/2"

D

5"

E

MEASURE INSIDE

7"

DIAMETER OF

F

LINER AT PLACES

9"

A, B, C, D, E, F

AND G ON "X" AND

G

"Y" AXES.

a.

Measure the inside bore of the cylinder liner at (A, B, C, D, E, F and G) on both the (X) and (Y) axis.

DIAL

2

INDICATOR

HOLD DOWN

CLAMP

0074-7