3.

filling

fuel.

4.

Avoid fueling equipment with the wrong fuel or

hydraulic systems or cooling systems with the

Maintain accurate records in a log documenting

amounts of fuel issued, by equipment USN number.

5. Ensure fuel availability for contingency

.

readiness, daily transportation, and construction

operations.

6. Maintain fire extinguishers on the tanker truck

as set forth in the U.S. Army Corps of Engineers, Safety

and Health Requirements Manual, EM 385-1-1.

7. Be alert to avoid environmental pollution. Fuel

spillage can be disastrous.

8. Daily communicate with the yard boss,

dispatcher, and the transportation supervisor.

9. Be a qualified professional operator of the fuel

truck.

Fuel-Handling Vehicle

Fuel-handling vehicles are classified as fuel tank

trucks or fuel tank semitrailers. Each vehicle has

distinguishing characteristics (model, size, and

capacity). The purpose of fuel-handling vehicles is to

load, haul, and discharge fuel to other vehicles, aircraft,

or fuel depots.

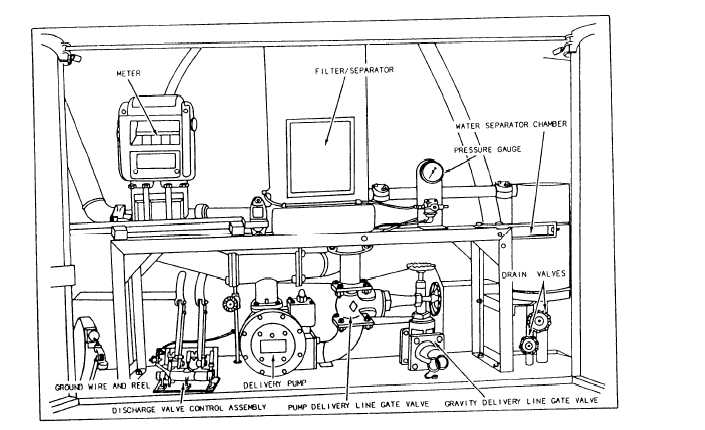

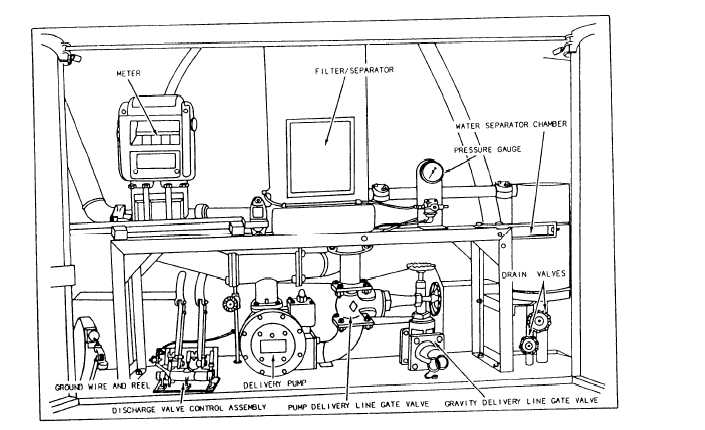

DESCRIPTION.— A typical fuel tank truck is

equipped with a tank body divided into compartments.

Each compartment has a manhole and filler cover

assembly, bottom sump or well, and discharge valves

with screen assemblies and drainpipes. The drainpipes

end in a manifold in the equipment Compartment. The

compartment (fig. 6-19) also houses a delivery pump, a

discharge valve control assembly, a pump delivery line

gate valve, an automatic dump valve, drain tube valves,

a gravity line gate valve, a filter separator, a pressure

gate, a meter, a water separator chamber, and a

grounding cable.

The delivery pump is powered by the power takeoff

(PTO), which is controlled by the PTO lever located in

the cab of the truck. The lever is moved backward to

the ENGAGED position to engage the PTO which

causes the pump to operate. The lever is moved forward

to the DISENGAGED position to disengage the PTO

and to stop the pump.

The discharge valve control assembly levers control

the discharge valves located at the bottom of each tank

Figure 6-19.-Dispensing equipment compartment.

6-25