Filter Rating

Filters are rated in several ways—absolute,

mean, and nominal. The absolute filtration rating

is the diameter in microns of the largest spherical

particle that will pass through the filter under a

certain test condition. This rating is an indication

of the largest opening in the filter element. The

mean filtration rating is the measurement of the

average size of the openings in the filter element.

The nominal filtration rating is usually interpreted

to mean the size of the smallest particles of which

90 percent will be trapped in the filter at each pass

through the filter.

Filter Elements

Filter elements generally may be divided into

two classes—surface and depth. Surface filters are

made of closely woven fabric or treated paper with

a uniform pore size. Fluid flows through the pores

of the filter material and contaminants are

stopped on the filter’s surface. This type of

element is designed to prevent the passage of a

high percentage of solids of a specific size. Depth

filters, on the other hand, are composed of layers

of fabric or fibers which provide many tortuous

paths for the fluid to flow through. The pores or

passages must be larger than the rated size of the

filter if particles are to be retained in the depth

of the media rather than on the surface.

Consequently, there is a statistical probability

that a rather large particle may pass through a

depth-type filter.

Filter elements may be of the 5-micron, woven

mesh, micronic, porous metal, or magnetic type.

The micronic and 5-micron elements have

noncleanable filter media and are disposed of

when they are removed. Porous metal, woven

mesh, and magnetic filter elements are usually

designed to be cleaned and reused.

5-MICRON NONCLEANABLE FILTER

ELEMENTS.— The most common 5-micron filter

medium is composed of organic and inorganic

fibers integrally bonded by epoxy resin and faced

with a metallic mesh upstream and downstream

for protection and added mechanical strength.

Filters of this type are not to be cleaned under

any circumstances and will be marked Disposable

or Noncleanable.

Another 5-micron filter medium uses layers

of very fine stainless-steel fibers drawn into a

random but controlled matrix. Filter elements

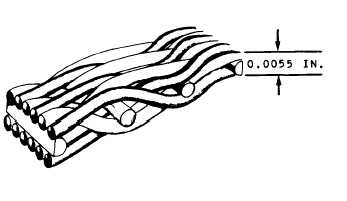

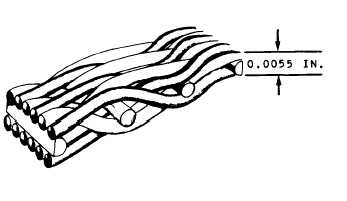

Figure 9-14.—Cross-section of a stainless steel hydraulic filter

element.

of this material may be either cleanable or

noncleanable, depending upon their construction.

WOVEN WIRE-MESH FILTER ELE-

MENTS.— Filters of this type are made of

stainless steel and are generally rated as 15 or 25

micron (absolute). Figure 9-14 shows a magnified

cross section of a woven wire-mesh filter element.

This type of filter is reusable.

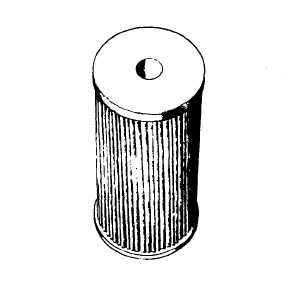

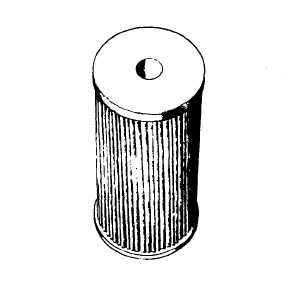

MICRONIC HYDRAULIC FILTER ELE-

MENT.— The term micronic is derived from the

word micron. It could be used to describe any

filter element; however, through usage, this term

has become associated with a specific filter with

a filtering element made of a specially treated

cellulose paper (fig. 9-15). The filter shown in

figure 9-10 is a typical micronic hydraulic filter.

This filter is designed to remove 99 percent of all

particles 10 to 20 microns in diameter or larger.

Figure 9-15.—Micronic filter element.

9-11

&