rise to a predetermined pressure, the valve

automatically returns to the neutral position and,

consequently, to open-center flow.

One of the advantages of the open-center

system is that the continuous pressurization of the

system is eliminated. Since the pressure is

gradually built up after the directional control

valve is moved to an operating position, there is

very little shock from pressure surges. This

provides a smooth operation of the actuating

mechanisms; however, the operation is slower

than the closed-center system in which the pressure

is available the moment the directional control

valve is positioned. Since most applications

require instantaneous operation, closed-center

systems are the most widely used.

HYDRAULIC POWER DRIVE SYSTEM

The hydraulic power drive has been used

in the Navy for many years. Proof of its

effectiveness is that it has been used to train and

elevate nearly all caliber guns, from the 40-mm

gun mount to the 16-inch turret. In addition to

gun mounts and turrets, hydraulic power drives

are used to position rocket launchers and

missile launchers, and to drive and control such

equipment as windlasses, capstans, and winches.

In its simplest form, the hydraulic power drive

consists of the following:

1. The prime mover, which is the outside

source of power used to drive the hydraulic pump

2. A variable-displacement hydraulic pump

3. A hydraulic motor

4. A means of introducing a signal to the

hydraulic pump to control its output

5. Mechanical shafting and gearing that

transmits the output of the hydraulic motor to the

equipment being operated

Hydraulic power drives differ in some

respects, such as size, method of control, and so

forth. However, the fundamental operating

principles are similar. The unit used in the

following discussion of fundamental operating

principles is representative of the hydraulic power

drives used to operate the 5"/38 twin mounts.

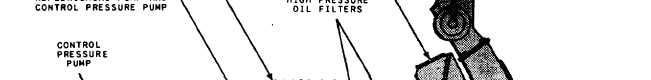

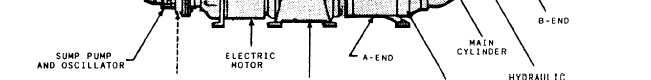

Figure 12-5 shows the basic components of

the train power drive. The electric motor is

constructed with drive shafts at both ends. The

forward shaft drives the A-end pump through

reduction gears, and the after shaft drives the

auxiliary pumps through the auxiliary reduction

gears. The reduction gears are installed because

Figure 12-5.-Train power drive—components.