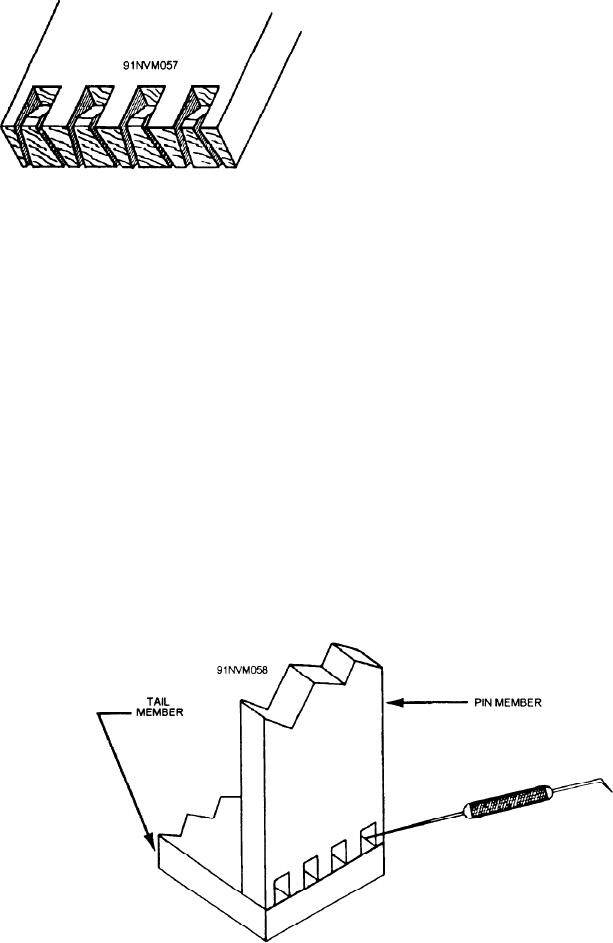

Box Corner and Miter Joints

The box corner joint is the same as a multiple

dovetail with one exception--the 10-degree angle

(refer to fig. 3-18). A miter joint (refer to fig. 3-19)

is made by mitering the ends or edges of the

members that are to be joined. The angle of the

miter cut is one-half of the angle formed by the

joined members. In rectangular frames, door

casings, boxes, and the like, adjacent members form

a 90-degree angle. The correct angle for mitering is

Figure 3-31.--Chiseling out waste in a through

multiple-dovetail joint.

45. For members that will form an equal-sided

figure with other than four sides (such as an octagon

off the outlines of the pins at 10 to the center lines.

or a pentagon), you need to calculate the correct

Determine the depth of the shoulder line by the

mitering angle. Do this by dividing the number of

thickness of the tail member.

sides the figure will have into 180, as shown in

figure 3-33.

You cut out the pins by sawing on the waste

sides of the lines and then chisel out the waste.

You can miter members in a wooden or metal

You should chisel halfway through from one side, as

miter box or on the circular saw by setting the miter

shown in figure 3-31. Then turn the member over

gauge to the desired angle. You can edge miter

and chisel through from the other side.

members to any angle on the circular saw by tilting

the saw.

When you have finished cutting out the pins, lay

the tail member flat. Set the ends of the pins in

Abutting surfaces of end-mitered members do

exactly the position they are to occupy (fig. 3-32).

not hold well when merely glued. You need to

Score the outlines of the pins, which will, of course,

reinforce them. A good reinforcement for a joint

also be the outlines of the tails. Square lines across

between end-mitered members is the slip feather.

the end of the tail member. Saw and chisel out the

This joint is a thin piece of wood or veneer glued

waste between the tails.

into a kerf cut in the thickness dimension of the

Figure 3-32.--Marking the tail member.

3-24