line left by the 45-degree miter cut. The ends of the

abutting members will then match the face of the

other member as shown in view D.

Mortise-and-Tenon Joints

The mortise-and-tenon joint is mostly used in

f u r n i t u r e and cabinet work. In the blind

mortise-and-tenon joint (refer to fig. 3-21), the

tenon does not penetrate all the way through the

mortised member. When the tenon penetrates all

the way through, it is a through mortise-and-tenon

joint. Besides the ordinary stub joint (fig. 3-37, view

A), there are haunched joints (view B) and

table-haunched joints (view C). Haunching and

table-haunching increase the strength and rigidity of

the joint.

MORTISE-AND-TENON LAYOUT.--You can

lay out an ordinary stub mortise-and-tenon joint

using the following steps:

1. Mark the faces of the members plainly.

2. Lay off the desired length of the tenon.

3. Square the shoulder line all the way around.

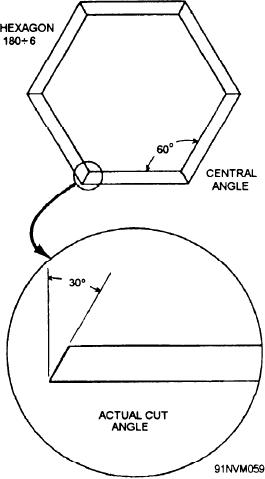

Figure 3-33.--Mitering angles.

4. Then, lay off the total width of the tenon

member on the mortise member, as shown in figure

joint. (See fig. 3-34 for a simple jig to use when

3-38.

making the kerf cut.) Saw about halfway through

from the outer to the inner corner. Apply glue to

5. Determine the thickness of the tenon. It is

both sides of the slip feather, and push the slip

usually between one-third and one-half the thickness

feather into the kerf (fig. 3-35). Clamp it tight and

of the mortise member.

allow the glue to dry. After it has dried, remove the

clamp and chisel off the protruding portion of the

6. Use a marking gauge to mark two lines (fig.

slip feather.

3-38). If the faces of the members are to be flush,

use the same gauge setting to score a double line on

Coping Joints

the mortise member. Remember to gauge from the

face of the member. If the face of the tenon

Inside corner joints between molding trim

member is to be set back from the face of the

members are usually made by placing the end of

mortise member, you should increase the mortising

one member against the face of the other. Figure

gauge setting by the amount of the setback.

3-36 shows the method of shaping the end of the

abutting member to fit the face of the other

7. Last, lay off from the end of the mortise

members. First, saw the end of the abutting

member and from the matching edge of the tenon

member square. Do this as you would an ordinary

member. Lay off by the amount of end stock that

butt joint between ordinary flat-faced members.

is to remain above the mortise.

Then, miter the end to 45, as shown by views A

and B of figure 3-36. Set the coping saw at the top

NOTE: You wouldn't need this last step of the

of the line of the miter cut. Hold the saw at 90 to

layout for a slip-tenon joint, like the one shown in

the lengthwise axis of the piece. Saw off the

figure 3-21.

segment as shown in view C. Closely follow the face

3-25