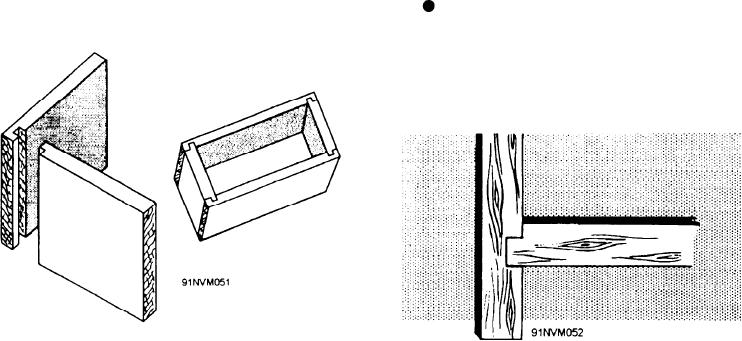

bare-faced tongue. The dado and rabbet joint (fig.

same. Change the height of the saw if the depth of

3-25) is another joint often used in making boxes,

the cheek is different.

drawers, and cabinets.

By using the dado head, you can cut most

The housed lock-joint (fig. 3-26) is a type of

rabbets in a single cut. First, build up a dado head

dado and rabbet joint. Note that the rabbeted piece

equal in thickness to the desired width of the cheek.

is reversed. The dadoed piece extends beyond the

Next, set the head to protrude above the table a

rabbeted piece. This joint is used extensively in the

distance equal to the desired depth of the shoulder.

pattern shop for manufacturing special wooden

Clamp a l-inch board to the fence to serve as a

foundry flasks. The dadoed piece extends to form

guide for the piece. Set the fence so the edge of

handles for the flask.

the board barely contacts the right side of the dado

head. Set the piece against the miter gauge that is

Dovetail Joints

set at 90 to the saw blade. Now hold the edge or

end to be rabbeted against the l-inch board and

The dovetail joint (refer to fig. 3-17) is the

make the cut.

strongest of all the woodworking joints. However,

its construction requires a lot of work; therefore,

On jointers, a rabbeting strip on the outboard

you will use dovetail joints only when working on

edge of the outfeed table depresses for rabbeting.

finer grades of furniture and cabinet work.

The strip is outboard of the end of the cutterhead.

To rabbet on a jointer, you depress the infeed table

A joint containing only a single pin is a single

and the rabbeting strip the depth of the rabbet

dovetail joint. A joint containing two or more pins

below the outfeed table. Set the fence the width of

is a multiple dovetail joint. A joint in which the

the rabbet away from the outboard end of the

pins pass all the way through the tail member is a

cutterhead. The unrabbeted part feeds onto the

through dovetail joint. A joint in which they pass

rabbeting strip when the piece feeds through.

only part way through is a blind dovetail.

The simplest dovetail joints is the half-lap

used in woodworking. The well-known

dovetail joint (fig. 3-27). This joint is first laid out

tongue-and-groove joint is actually a combination of

and cut like an ordinary end half lap. The end of

the groove and the rabbet. The tongued member is

the lapping member is laid out for shaping into a

simply a member rabbeted on both faces. In some

dove tail as follows:

types of panel work, the tongue is made by

rabbeting only one face. A tongue of this kind is a

Set the T-bevel to 10. This is the correct

angle between the vertical axis and the sides of a

dovetail pin or tail. You can set the bevel with a

protractor or with the protractor head on the

Figure 3-25.--Dado and rabbet joint.

Figure 3-26.--Housed lock-joint.

3-22