In the cross half-lap joint, you should chisel the

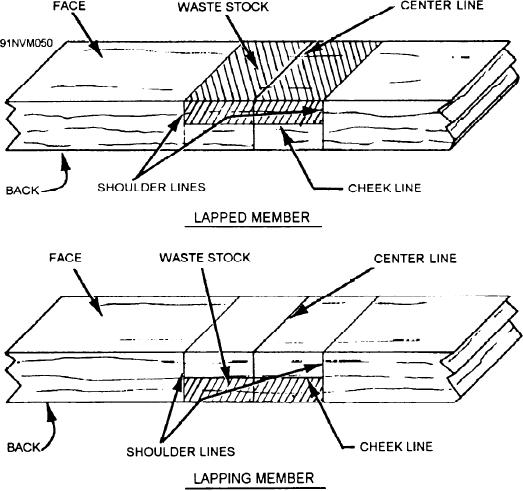

A cross half-lap joint (fig. 3-24) between

waste out rather than saw it out. To make the

members of equal cross-section dimensions is laid

chiseling easier, remove as much stock as possible

out and cut as follows: If the members are of the

with the saw first. Saw a series of kerfs between the

same length and they are to lap each other at the

shoulder cuts. In chiseling, make a roughing cut

midpoint, place them face-to-face with ends flush.

down to just above the cheek line with a firmer

Then square a center line all the way around. To

chisel and mallet. Hold the chisel bevel down.

test the accuracy of the center calculation, turn one

Finish off the bottom with a paring chisel while

of the members end for end. If the center lines still

holding the chisel bevel up.

meet, the center location is correct.

You can use a circular saw to cut half-lap

When making a cross half-lap joint, you should

recesses and cross half-lap recesses. For an end

put the best wide surfaces up and mark each face

half-lap recess, set the table saw blade above the

plainly. Lay off one-half the width of a member on

table a distance equal to one-half the thickness of a

either side of the center lines; then, square the

member. Place the member against the miter

shoulder lines all the way around. Again check for

gauge, set it at 90 to the saw blade, and make the

accuracy by turning a member end for end. If the

shoulder cut. Take out the remaining waste by

shoulder lines meet, the layout is accurate. Next,

making as many recuts as necessary.

gauge one-half the thickness of a member. Do this

from the face of each member and score check lines

For a cross half-lap recess, you should proceed

on the edges between the shoulder lines. Next,

as follows: Set the table saw blade or dado head so

make the shoulder cuts, sawing from the back of the

its height above the table is equal to one-half the

lapping member and from the face of the lapped

thickness of a member. Then, place the member

member.

against the miter gauge set at 90 to the saw blade

Figure 3-24.--Gross half-lap joint.

3-20