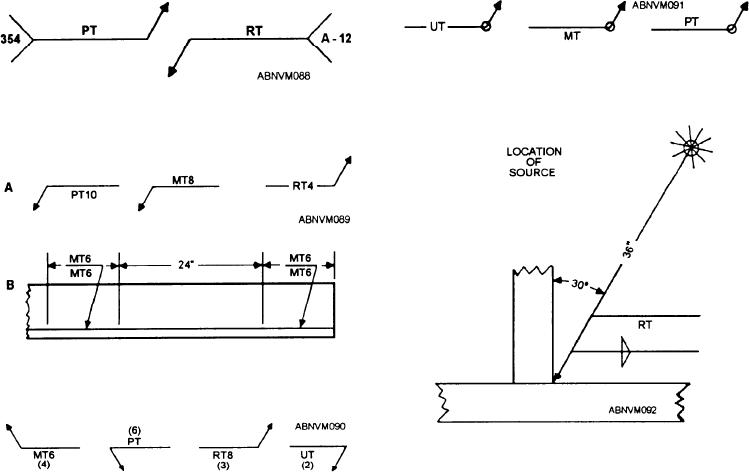

Figure 11-20.--Specify tests to be made all around.

Figure 11-17.--Location of specification, process,

classification, or reference.

Figure 11-18.--Specifying length and exact location of area to

be tested.

Figure 11-21.--Combining nondestructive testing symbols

and welding symbols.

Figure 11-19.--Specify number of tests to be made at random.

HYDROSTATIC TESTING

The length of the section to be tested is specified as

shown in figure 11-18. To specify tests of welds or parts

Fluid systems are hydrostatically tested during

where only the length of the section need be considered,

initial construction, subsequent to repairs, and

the length in inches is shown to the right of the basic

periodically to verify the integrity of the system. All

piping sections that have been removed for repairs and

test symbol (fig. 11-18, view A). To show the exact

newly fabricated sections must be hydrostatically tested

location of the section to be tested as well as its length,

before installation to make sure that there will be no

dimension lines are used as shown in view B. When the

leaks under operating conditions. Operational tests are

full length of a part is to be tested, no length dimensions

also preformed, instead of hydrostatic tests, after certain

need be shown on the testing symbol.

repairs involving mechanical joints. The basic purpose

If a number of tests are specified to be taken at

of all such tests is to ascertain that the system can

random, the desired number of tests are placed in

perform its intended function safely and reliably. This

parentheses, as shown in figure 11-19.

section will discuss hydrostatic tests, operational tests,

and the equipment used to conduct these tests.

To specify tests that are to be made all around a part,

the test-all-around symbol is used with the basic test

HYDROSTATIC TESTS

symbol, as shown in figure 11-20.

Nondestructive testing symbols may be combined

Hydrostatic testing of piping systems is

with the standard welding symbols previously

accomplished whenever repairs are made to piping

discussed. This feature increases the scope of all

system or any related components. Hydrostatic testing

welding symbols. The length of a section to be tested

of ships' systems is required every 8 years, and should

can be indicated, and individual areas for testing can be

be conducted before or during the early stages of a

specified by means of these symbols. Figure 11-21

scheduled major overhaul of the ship. Regardless of the

shows the combining of nondestructive testing symbols

reason for testing, all hydrostatic testing is

accomplished in the same general manner using the

and welding symbols.

11-16