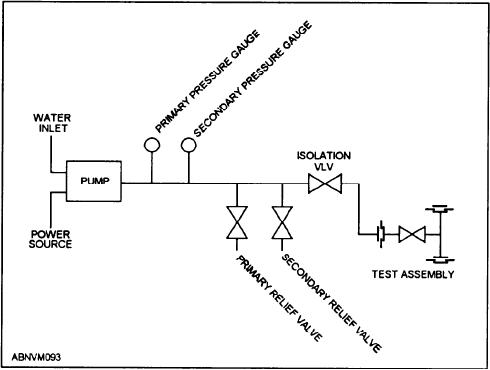

PRESSURE GAUGES.--When performing

same equipment. Hydrostatic testing of systems or

components is commonly referred to as "H" pressure

hydrostatic tests, use two independent pressure gauges.

tests. These tests of piping systems should be at a

These two gauges will indicate actual hydrostatic test

pressure of 135 percent above the maximum system

pressure. One of the gauges will be the master gauge

design pressure, but in no case less than 50 psi. The line

and the other will be the backup gauge. Use the master

drawing in figure 11-22 shows a simple hydrostatic test

hydrostatic test gauge readings as the true hydrostatic

setup and associated equipment.

test pressure throughout the test.

Master Gauge. --Master test gauges are used to

Hydrostatic Testing Equipment

indicate actual hydrostatic test pressures. The scale

range of the master test gauge should be greater than the

Shop hydrostatic testing of piping systems or

maximum test pressure, but should not exceed 200

components should be conducted in an area that can be

percent of the maximum test pressure. Master test

secured from all traffic. This area should also provide

gauges shall have a valid calibration label according to

the operator protection in event of component failure.

NAVSEA OD 54845, Metrology Requirements List.

When hydrostatic testing the ship's piping system, set

Backup Gauge. --A backup gauge is used to check

up the equipment in an area that can be secured from all

and verify the accuracy of the master test gauge. Like

unwanted traffic. The equipment required for

the master gauge, the backup gauge is also subject to

hydrostatic testing includes a pump, two pressure

actual test pressure. The scale range of the backup test

gauges, two relief valves, a cutoff valve, blank flanges,

gauge should also be greater than the maximum test

gaskets, and clamps.

pressure, but should not exceed 200 percent of the

PUMPS.--There is no specific requirements for

maximum test pressure. Backup test gauges shall also

the type of pump to be used for hydrostatic testing. The

have a valid calibration label according to NAVSEA OD

pump must be large enough to deliver the required

54845, Metrology Requirements List.

pressure and water volume to the system being tested.

RELIEF VALVES. --Relief valves provide for

Pneumatic pumps are the most common type of pump

overpressure protection of the system or component,

used for hydrostatic testing and are operated by the

equipment, and safety of personnel. The relieving

ship's compressed air system. These pumps are usually

rated in gallons per minute.

capacity, at test pressure of relief valves used for

Figure 11-22.--Hydrostatic test equipment and set up.

11-17