This combination contains no free crystals of

ELASTICITY

ferrite; instead, it consists of crystals of pearlite

As previously noted, a deformation or change of

surrounded by cementite at the grain boundaries.

shape (strain) occurs when a material is subjected to

external forces that cause stresses in the material. The

ability of a material to return to its original size and

PROPERTIES OF METAL

shape after strain is the property known as elasticity.

All materials are elastic to some extent. It may

A PHYSICAL PROPERTY is a characteristic of a

surprise you to learn that a piece of steel is more elastic

metal that may be observed or measured. The physical

than a rubber band. The rubber band stretches more

properties of steel are affected by the following:

than the steel since it is more easily strained, but the

steel returns more nearly to its original shape and size

Carbon content

and is, therefore, more truly elastic. Glass is also more

elastic than rubber.

Addition of various alloying metals

The greatest stress that a material is capable of

withstanding without taking a permanent set (that is

Heat treatment

without becoming permanently deformed) is known

as the ELASTIC LIMIT. Below the elastic limit, the

The particular properties that we require of any

amount of strain is directly proportional to the amount

metal or alloy depend upon the use we will make of

of stress and, therefore, to the amount of externally

the material. For example, an anchor chain must have

applied force. Above the elastic limit, however, the

the property of toughness; a boiler tube must have high

amount of deformation that results from an increase in

tensile strength, the ability to conduct heat, and the

load is way out of proportion to the increase in load.

ability to resist deformation or creep at high

temperatures; an electric wire must be able to conduct

Strain may be axial, angular, or both, depending

electricity; a knife blade must have the property of

upon the nature of the applied load and the stresses

hardness; a spring must be elastic; a saltwater piping

that are developed within the material to withstand the

system must resist corrosion; and a piece of metal that

applied load. When the elastic limit is exceeded

is to be drawn out into a wire must possess the property

through the application of an axial load, the material

known as ductility. The following sections deal with

w i l l be permanently deformed either by

some important properties of metals and alloys.

ELONGATION or by COMPRESSION. When the

applied load is not axial (as in shear and torsion), the

resulting strain is angular and, if permanent

deformation results, the deformation is also angular.

As noted before, the amount of strain is propor-

tional to the amount of stress up to (or almost up to) the

elastic limit. The ratio of stress to strain is, therefore, a

constant for each material. This constant, which is

called the MODULUS OF ELASTICITY, is obtained

by dividing the stress by the strain, which is the elonga-

tion caused by that stress. For example, suppose that a

certain material is so loaded that the internal stress

developed in tension is 30,000 psi and that with this

stress the material elongates or is strained 0.0015 inch

per inch. The modulus of elasticity (E) of this material

is

Stress (psi)

E=

Elongation (inch per inch)

30,000 psi

= 0.0015 inch per inch

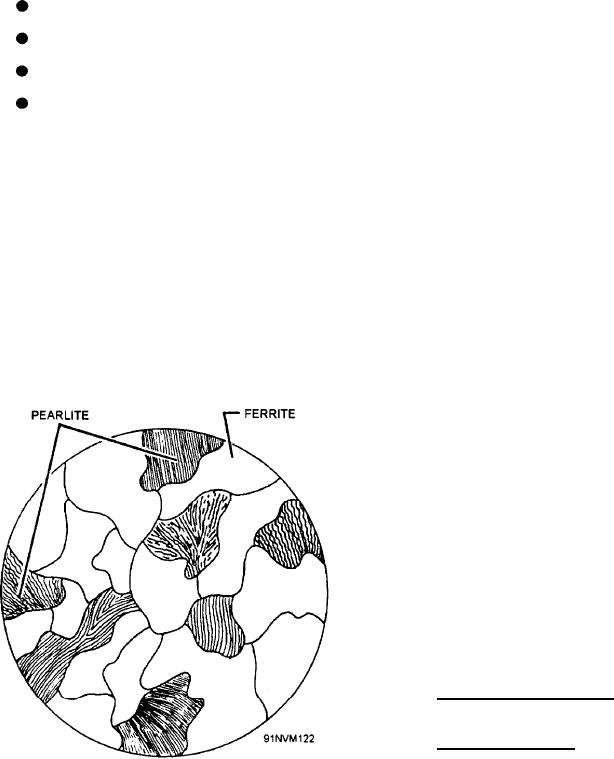

Figure 6-8.--Typical structure of steel containing less than

= 20,000,000 psi

0.85 percent carbon.

6-7