increased a certain amount, which will be a percent-

age of the original length.

Stress occurs because molecular forces within the

material resist the change of shape that an applied

load tends to produce. In other words, stress results

from the resistance of the molecules to being shifted

around, pulled apart, or squeezed together. Because

stress involves molecular forces, a piece of metal that

is subjected to a load develops an enormous number

of stresses, rather than just one stress. If you had more

than a very few molecules, you would have to draw

thousands or perhaps millions of arrows to indicate all

the molecular forces involved. We often speak of

stress as though it were one internal force, acting in

one direction; that is, the direction opposite to the

direction of the applied load. In other words, we con-

sider the TOTAL EFFECT of all the molecular

stresses, rather than trying to consider each set of

molecular stresses separately.

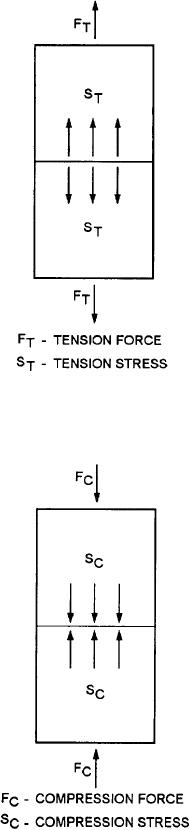

Figure 6-1.--Tension forces and tension stresses.

The manner in which the load is applied deter-

mines the type of stress that will develop. Applied

forces are usually considered as being of three basic

kinds: tension (or tensile) forces, compression forces,

and shearing forces. The basic stresses, therefore, are

tension (or tensile) stresses, compression stresses, and

shearing stresses. Complex stresses such as bending

or more of the basic stresses.

TENSION STRESS

Tension stresses develop when a material is sub-

jected to a pulling action. If, for example, a cable is

fastened to an overhead clamp and a weight is at-

tached to the free end, tension stresses develop within

the cable. The tension stresses resist the tension forces

that tend to pull the cable apart. Figure 6-1 shows

tension forces and the resulting "equal and opposite"

tension stresses.

COMPRESSION STRESS

Figure 6-2.--Compression forces and compression stresses.

Compression stresses develop within a material to

oppose the forces that tend to compress or crush the

SHEARING STRESS

material. A column that supports an overhead weight

is said to be in compression, and the internal stresses

Shearing stresses develop within a material when

that develop within the column are compression

opposite external forces are applied along parallel

stresses. Figure 6-2 shows compression forces and

lines in such a way as to tend to cut the material.

compression stresses.

Shearing forces tend to separate material by sliding

6-3