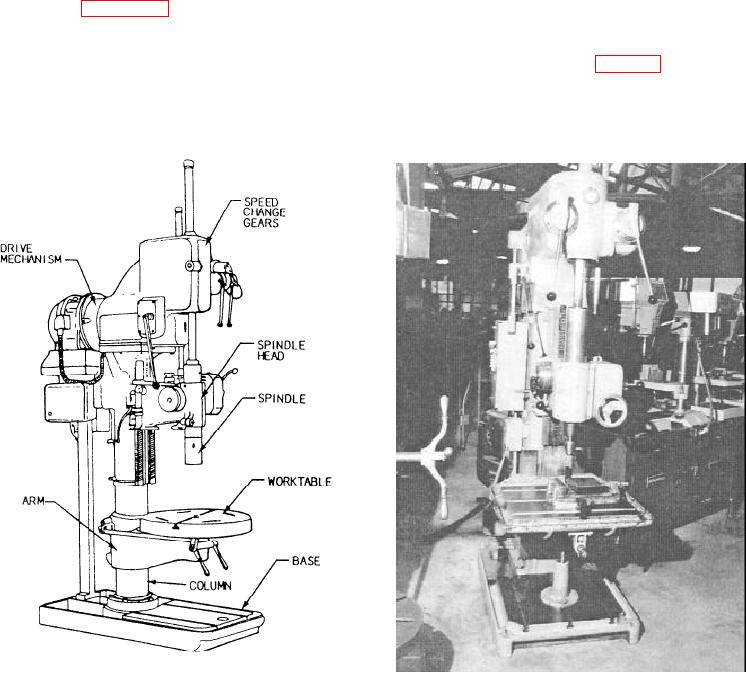

drill press and the radial drill press. These machines

The column supports the work table, the drive

have similar operating characteristics but differ in that

mechanism and the spindle head.

you position the drilling lead on the radial drill, and

The work table and arm can be swiveled around

you position the workpiece on the upright drill.

the column and can be moved up or down to adjust for

height. In addition, the work table may be rotated

UPRIGHT DRILL PRESSES

360 about its own center.

Upright drill presses discussed in this section will

The spindle head guides and supports the spindle

be the general purpose, the heavy duty, and the

and can be adjusted vertically to provide maximum

sensitive drill presses. Nearly all ships have one or

support near the spindle socket.

more of these types. They are classified primarily by

The spindle is a splined shaft with a Morse taper

the size of drill that can be used, and by the size of the

socket to hold the drill. The spline permits vertical

work that can be set up.

movement of the spindle while it is rotating.

The drive mechanism includes the motor, speed

General Purpose Drill Press (Round Column)

and feed change gears, and mechanical controls.

Heavy Duty Drill Press (Box Columns)

press is the most common type of machine found in

Navy machine shops. The basic components of this

machine are shown in the illustration.

used to drill large holes. It differs from the general

The base has a machined surface with T-slots for

purpose drill press in that the work table moves only

heavy or bulky work.

28.477

Figure 4-24.--General purpose drill press.

Figure 4-25.--Heavy duty drill press.

4-15