the column. The spindle head may be traversed

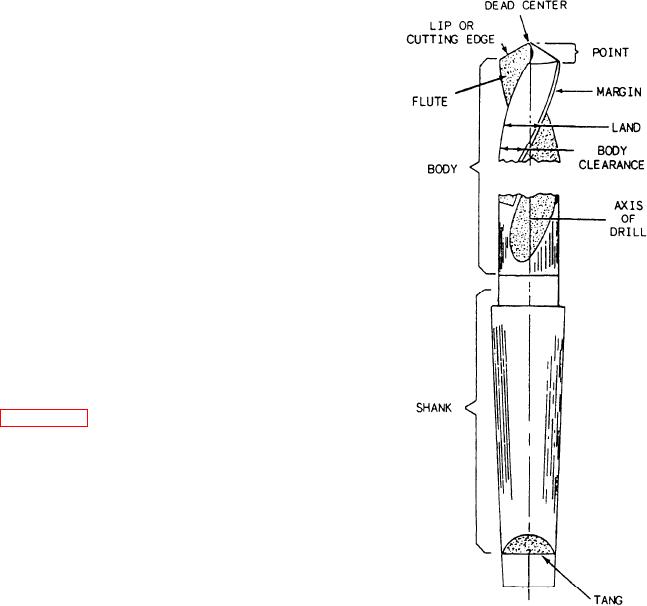

drill is the metal column that separates the flutes. It

horizontally along the ways of the arm, and the arm

runs the entire length of the body between the flutes

may be moved vertically on the column. This

and gradually increases in thickness toward the shank,

machine is especially useful when the workpiece is

giving additional rigidity to the drill.

bulky or heavy or when you need to drill many holes

with one setup. The arm and spindle are designed so

The tang is found only on tapered-shank tools. It

that the drill can be positioned easily over the layout

fits into a slot in the socket or spindle of the drill press

of the workpiece.

and bears a portion of the driving strain. Its principal

purpose is to make it easy to remove the drill from the

Some operational features that are common to

socket with the aid of a drill drift. (NEVER use a file

most radial drill presses are: (1) high- and low-speed

or screwdriver to do this job.)

ranges provided from either a two-speed drive motor

or a low-speed drive gear; (2) a reversing mechanism

The shank is the part of the drill that fits into the

to change the direction of rotation of the spindle by

socket, spindle, or chuck of the drill press. The types

either a reversible motor or a reversing gear in the

of shanks that are most often found in Navy machine

drive gear train; (3) automatic feed mechanisms that

are driven from the spindle and feed the cutting tool at

a selected rate per revolution of the spindle; (4) depth

setting devices that permit the operator to preset the

required depth of penetration of the cutting tool; and

(5) coolant systems to provide lubrication and coolant

to the cutting tool.

On other machines you can place the control

levers in different positions; however, they serve the

same purposes as those shown. Use the locking

clamps to lock or "dog down" the table or head of a

drill after it is positioned over the work. But make

sure the locking action does not cause the drill or

work to move slightly out of position.

TWIST DRILL

The twist drill is the tool generally used to drill

holes in metal. This drill is formed either by forging

and twisting grooves in a flat strip of steel or by

milling a cylindrical piece of steel.

twist drill: the body, the shank, and the point. The

portion of the land behind the margin is relieved to

provide body clearance. The body clearance helps

edge, and the area called the lip clearance is on the

cone of the drill. The dead center is the sharp edge

located at the tip end of the drill. It is formed by the

intersection of the cone-shaped surfaces of the point

and should always be in the exact center of the axis of

the drill. Do not confuse the point of the drill with the

Figure 4-28.--The parts of a twist drill.

dead center. The point is the entire cone-shaped

surface at the cutting end of the drill. The web of the

4-17