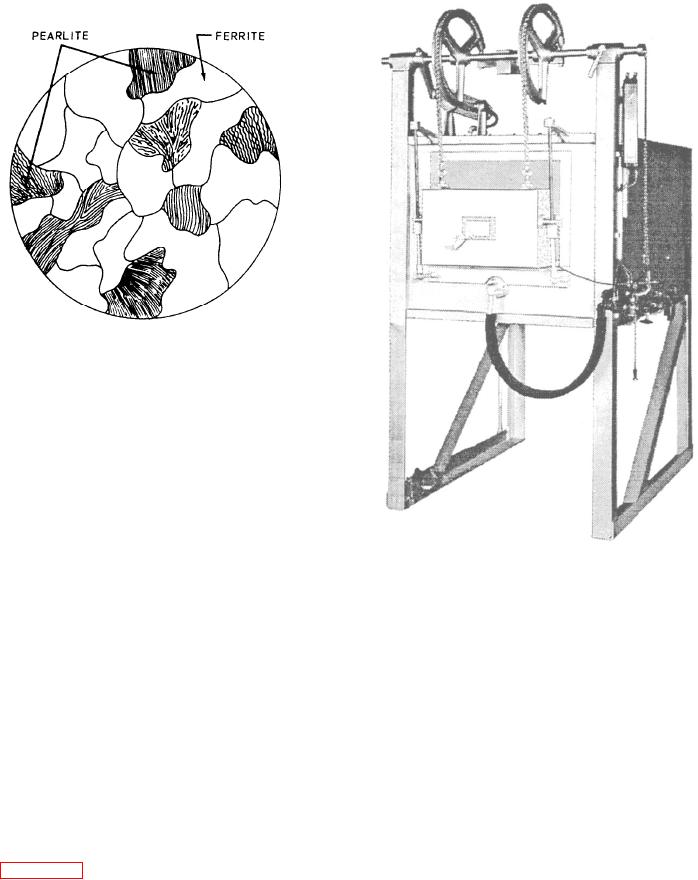

Figure 15-5.--Typical structure of low-carbon steel.

The structure of an alloy is described as being a

MECHANICAL MIXTURE when two or more

structural forms are mixed together but are still

separately distinguishable. A mechanical mixture of an

alloy is comparable-though on a smaller scale-to the

mixture of sand and gravel in concrete.

One of the most important mechanical mixtures that

occurs in many steels is known as PEARLITE. Pearlite,

so called because it has a pearly luster when seen under

a microscope, is an intimate mechanical mixture of

Figure 15-6.--Controlled atmosphere electric furnace used for

ferrite and cementite in alternate plates or layers. Ferrite

heat-treating.

is a solid solution, and cementite or iron carbide is an

intermetallic compound; in pearlite, the two are closely

HEAT-TREATING EQUIPMENT

mixed to form a characteristically layered structure.

The equipment required for heat-treating consists

When the entire structure of the alloy is in the form of

of furnaces or other heating devices, quenching baths

or other cooling devices, temperature controls and

indicators, and other controls and indicators required

is called the EUTECTOID or the EUTECTOID

for the proper operation of the equipment or for the

STRUCTURE.

control of the process. In addition, heat-treating equip-

The internal structure of an alloy may show various

ment includes tongs and other devices for handling and

holding the work while it is being heated or cooled.

metallic compounds, and mechanical mixtures. Many

Because heat-treating equipment varies so widely,

it is not practical to describe or to give operating

instructions for different types in this course. The

alloy. Figure 15-5 shows, very much enlarged, a typical

equipment described here is typical of heat-treating

combination that occurs when plain-carbon steel

equipment you may be required to use, but it does not

containing less than 0.83 percent carbon is heated to a

include all possible types of equipment. If you are

certain temperature and then cooled slowly. This

required to heat-treat metals, find out all you can about

combination consists of the solid solution ferrite and the

the equipment that is available before you begin to use

mechanical mixture pearlite, each in crystal form,

it. The instructions furnished by the manufacturer are

distributed throughout the alloy. The relative

usually your best-and sometimes only-source of

proportions of ferrite and pearlite in this combination

authoritative information on a specific item of heat-

treating equipment.

depend largely upon the carbon content of the alloy.

15-6