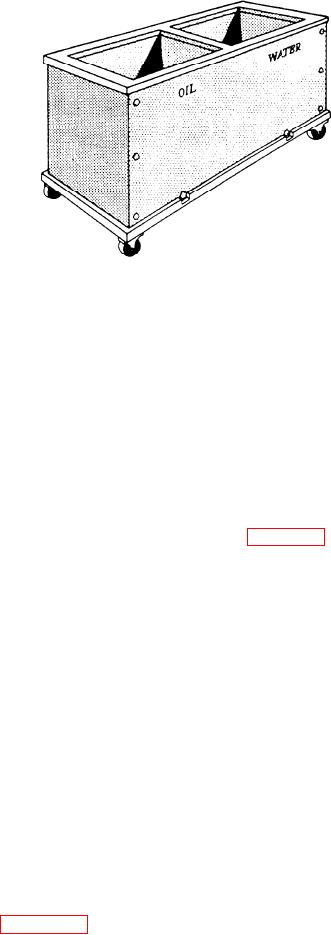

tight to prevent mixing of the mediums. Each

compartment is equipped with a drain plug, a screen in

the bottom to catch scale and other foreign matter, and

a mesh basket to hold the parts being quenched. The

mesh basket and the wire screen are suspended in the

tank and held in position by clips that fit over the rim of

the tank A portable electric pump may be attached to

the rim of the tank to circulate the liquid.

Stationary quenching tanks are usually designed to

contain only one liquid. In a stationary quenching tank,

the mesh basket that holds the work is usually raised

and lowered by air pressure and is controlled by a three-

way air valve. The basket can usually be positioned at

any level and can be raised above the level of the liquid

so the parts can be drained after they have been cooled.

Figure 15-10.--Portable quenching tank for use in heat-treating.

Stationary quenching tanks usually have built-in

electric pumps to circulate the liquid. WATER is often

used as a quenching medium for plain-carbon steels and

cooling is much faster than when the cooling medium

for aluminum and other nonferrous metals. The water

is not in motion. The volume of the cooling medium is

must be kept clean by frequent changing. The

also important. As the metal cools, the cooling medium

absorbs heat. If the volume is insufficient, the cooling

temperature most often used for water quenching is

about 65F. Normally, the volume of water in the tank

medium will become too hot to cool the work at the

required rate. In regular heat-treating shops where the

should prevent a temperature rise of more than 20F.

cooling mediums must be used continuously,

When very heavy pieces are being quenched, the

mechanical cooling systems are used to maintain the

temperature rise may exceed 20F, but it should always

cooling medium at the correct temperature.

be kept as low as possible.

Liquids, gases, and solids are all used as cooling

BRINE is used for many quenching operations. At

mediums for heat-treating operations. Table 15-3 shows

any given temperature, brine cannot hold as much

dissolved air as fresh water can hold. With brine,

the relative cooling rates of some commonly used

liquids and gases. Solid materials such as lime, sand,

therefore, there are fewer air bubbles or gas pockets on

ashes, and cast-iron chips are sometimes used when the

the surface of the work Brine wets the surface more

rate of cooling must be slower than that produced by

thoroughly and cools the work more rapidly and more

liquids or gases.

uniformly than plain water.

Liquid quenching is accomplished either by

Brine solutions usually contain from 7 to 10 percent

S T I L L - B A T H QUENCHING or by FLUSH

salt by weight or 3/4 of a pound of salt for each gallon

QUENCHING. In still-bath quenching the metal is

of water. The correct temperature for a brine quench

cooled in a tank of still liquid. The only movement of

ranges from 65 to 100F. Plain-carbon steels and low-

the liquid is that caused by the movement of the hot

alloy steels are often quenched in brine. High-carbon

metal. Flush quenching is used for parts that have

steels and all alloy steels that are uneven in cross section

recesses or cavities that would not be properly quenched

must be quenched very carefully if brine is the cooling

by the still-bath method. In flush quenching, the liquid

medium. Brine cools the material so rapidly that great

is sprayed under pressure onto the surface of the piece

internal stresses may develop and crack the work Brine

and into every cavity or recess. This procedure is often

is not used as a quenching medium for nonferrous

used to minimize distortion by providing a relatively

metals because of its high corrosive effect on these

uniform quench to all parts of the piece.

metals.

Portable quenching tanks of the type shown in

OIL is used to quench high-speed steels and

oil-hardened steels. It is also the preferred quenching

not have permanent, built-in equipment. Portable

medium for almost all other steels except where the

quenching tanks may have one compartment or several.

necessary hardness cannot be obtained by such a

When more than one quenching medium is to be used,

relatively slow quench. Although nonferrous metals are

the seal between the compartments must be absolutely

not normally quenched in oil, they may be in special

15-11