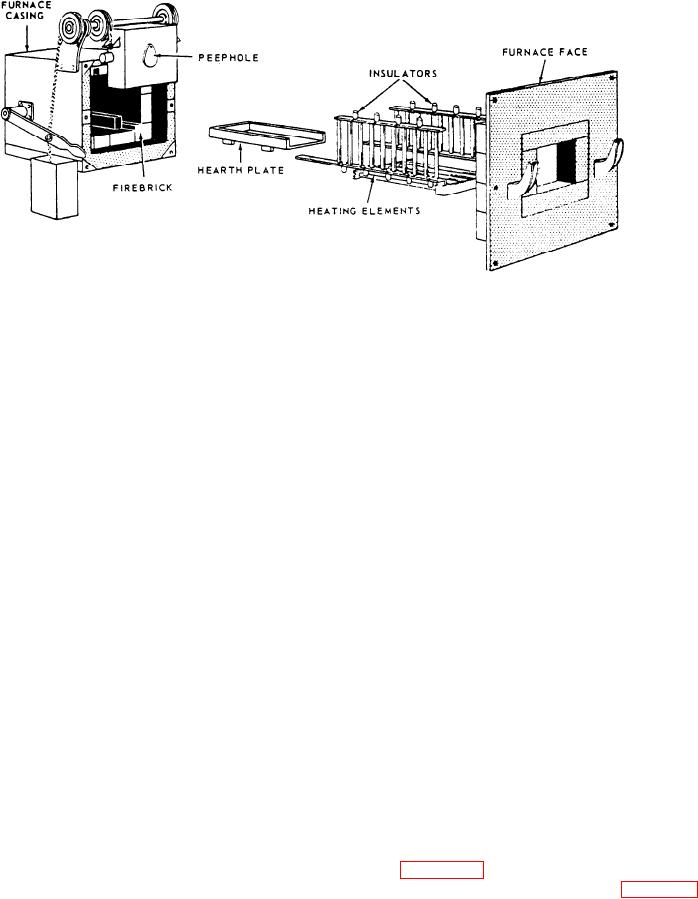

Figure 15-7.--Exploded view of electric furnace used for heat-treating.

avoided, however, a neutral atmosphere rather than a

HEATING EQUIPMENT

reducing or oxidizing atmosphere is used.

Equipment designed for the heating of metals

A NEUTRAL ATMOSPHERE is neither oxidizing

includes electric furnaces, fuel-fired furnaces, bath

nor reducing because it contains no oxygen (oxidizing

furnaces, and devices for the measurement and control

agent) and no carbon monoxide (reducing agent). In

of temperature. Improvised heating devices may

reality, other factors often tend to produce either

include oxyacetylene torches, Hauck burners, forges,

oxidation or decarburization; therefore, an atmosphere

and temporary ovens constructed of firebrick and sheet

that is described as neutral may not always be totally

asbestos. We will discuss electric furnaces since they

neutral.

are what most Machinery Repairmen will be using.

The furnace atmosphere may be the result of the

The gases that circulate through the furnace heating

deliberate introduction of a gas or a mixture of gases

chamber and surround the metal as it is being heated

into the heating chamber. When gases are deliberately

make up the FURNACE ATMOSPHERE. By con-

introduced into the heating chamber for the purpose of

trolling the composition of the furnace atmosphere, you

controlling the atmosphere, the furnace is said to have

can produce the type of atmosphere best suited for the

a CONTROLLED or PROTECTIVE ATMOSPHERE.

heating of a particular type of metal. Furnace

atmospheres are generally classified as being oxidizing,

Electric Furnaces

reducing, or neutral.

An OXIDIZING ATMOSPHERE exists when

Electric furnaces with a controlled atmosphere are

frequently used for heat-treating on repair ships and

excess air is circulated through the furnace. Some

tenders. Quite often two such units are used on the same

electric furnaces are designed to operate with an

ship. One is a relatively low-temperature furnace used

oxidizing atmosphere at all times. An oxidizing

atmosphere is indicated by bright, clean walls and a

for preheating or tempering, and the other is a higher

temperature furnace used for hardening. Both types are

clear, transparent atmosphere in the furnace. Metals

equipped with control devices for regulating

heated in an oxidizing atmosphere occasionally develop

films of metal oxides (scale) on their surfaces. In some

temperature. The high-temperature furnace may also be

equipped with rheostats used to increase the rate of

cases, this is undesirable; but in other cases, it is desir-

heating. A typical electric furnace for shipboard use is

able because it tends to prevent further decarburization

of the metal. Decarburization is a term used to describe

the loss of carbon from the surface of ferrous metals

The outer casing of the furnace is usually made of

with consequent softening of the material.

A REDUCING ATMOSPHERE tends to remove

sheet steel. Just inside the casing is a layer of insulating

oxygen from the surface of the metal. A reducing

material, such as mica, spun glass, or asbestos. Inside

atmosphere is often desirable in heat treatment since it

this insulating material is a lining of refractory material,

tends to prevent oxide formation and other surface

such as firebrick and insulating brick. The refractory

lining insulates the furnace, helps maintain the required

15-7