TM 55-2815-574-24

0156

DISASSEMBLY - Continued

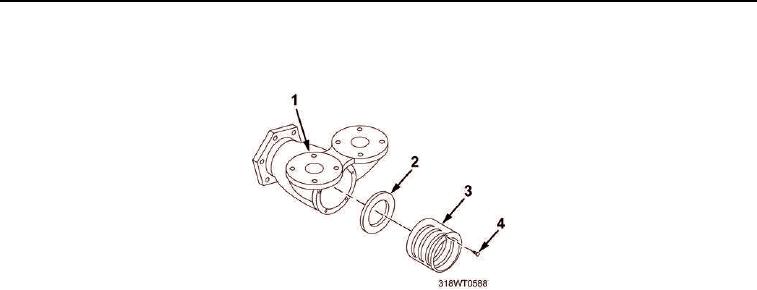

Figure 7. Slotted Screw, Cam, and Wear Plate.

END OF TASK

CLEANING

CAUTION

Do not clean shielded bearing in solvent. Dirt may be washed in and solvent may not be

removed. Failure to comply may result in damage to equipment.

1.

Using cleaning cloth, wipe bearing (Figure 6, Item 4) clean.

2.

Using cleaning cloth, clean exterior of raw water pump.

END OF TASK

INSPECTION

1.

Inspect bearing (Figure 6, Item 4) for external damage. Replace bearing if damage is found.

2.

Hold inner race and spin bearing (Figure 6, Item 4) slowly to detect any internal wear or rough spots.

Replace bearing if damage is found.

3.

Inspect all parts for cracks, burring or wear and replace as necessary.

4.

Inspect oil seal contact surfaces on shaft (Figure 6, Item 3) for scratches or grooves. Use fine abrasive cloth

to remove scratches.

5.

Inspect impeller (Figure 1, Item 2). Ensure bond between neoprene and metal is still good. Ensure blades

do not have a permanent set. Replace impeller as necessary.

6.

Inspect impeller blades for deformation.

7.

Inspect wear plate (Figure 7, Item 2) and remove any burrs from wear plate. If wear is excessive, reverse or

replace wear plate.

END OF TASK

ASSEMBLY

1.

Install wear plate (Figure 7, Item 2) over dowel in housing (Figure 7, Item 1).