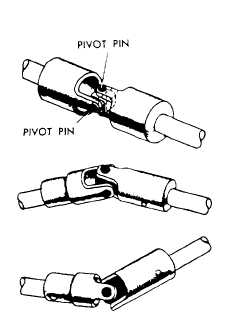

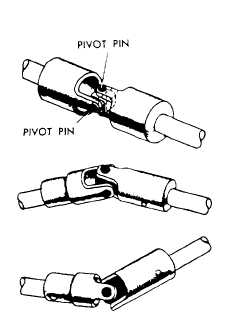

Figure 11-21.-Universal joint (Hooke type).

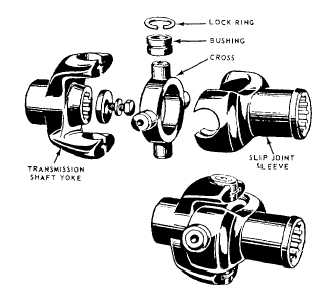

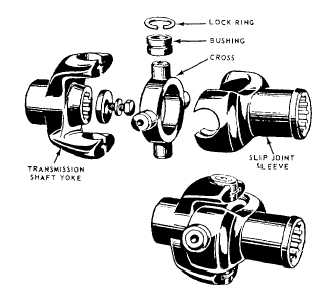

Figure 11-22.-Ring-and-trunnion universal joint.

forms. They are used in nearly all types and classes of

machinery. An elementary universal joint, sometimes

called a Hooke joint (fig. 11-21), consists of two

U-shaped yokes fastened to the ends of the shafts to be

connected. Within these yokes is a cross-shaped part that

holds the yokes together and allows each yoke to bend,

or pivot, in relation to the other. With this arrangement,

one shaft can drive the other even though the angle

between the two is as great as 25° from alignment.

Figure 11-22 shows a ring-and-trunnion universal

joint. It is merely a slight modification of the old Hooke

joint. Automobile drive shaft systems use two, and

sometimes three, of these joints. You will read more

about these in chapter 13 of this book.

The Bendix-Weiss universal joint (fig. 11-23)

provides smoother torque transmission but less

structural strength. In this type of joint, four large balls

transmit the rotary force, with a smaller ball as a spacer.

With the Hooke type universal joint, a whipping motion

occurs as the shafts rotate. The amount of whip depends

on the degree of shaft misalignment. The Bendix-Weiss

joint does not have this disadvantage; it transmits rotary

motion with a constant angular velocity. However, this

type of joint is both more expensive to manufacture and

of less strength than the Hooke type.

CAMS

A cam is a rotating or sliding piece of machinery (as

a wheel or a projection on a wheel). A cam transfers

motion to a roller moving against its edge or to a pin free

to move in a groove on its face. A cam may also receive

motion from such a roller or pin. Some cams do not

move at all, but cause a change of motion in the

contacting part. Cams are not ordinarily used to transmit

power in the sense that gear trains are used. They are

used to modify mechanical movement, the power for

which is furnished through other means. They may

control other mechanical units, or they may synchronize

or lock together two or more engaging units.

Cams are of many shapes and sizes and are widely

used in machines and machine tools (fig. 11-24). We

classify cams as

1. radial or plate cams,

2. cylindrical or barrel cams, and

3. pivoted beams.

A similar type of cam includes drum or barrel cams,

edge cams, and face cams.

The drum or barrel cam has a path cut around its

outside edge in which the roller or follower fits. It

imparts a to-and-from motion to a slide or lever in a

plane parallel to the axis of the cam. Sometimes we build

these cams upon a plain drum with cam plates attached.

Plate cams are used in 5"/38 and 3"/50 guns to open

the breechblock during counter-recoil.

Edge or peripheral cams, also called disc cams,

operate a mechanism in one direction only. They rely on

gravity or a spring to hold the roller in contact with the

edge of the cam. The shape of the cam suits the action

required.

11-12