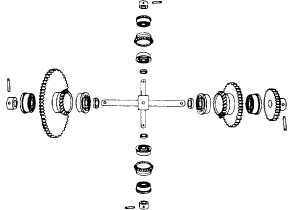

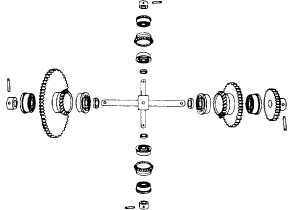

Figure 11-9.-Exploded view of differential gear system.

Other Types of Springs

Torsion bars (fig. 11-7, C) are straight bars that are

acted on by torsion (twisting force). The bars may be

circular or rectangular in cross section. They also may

be tube shaped; other shapes are uncommon.

A special type of spring is a ring spring or disc spring

(not illustrated). It is made of several metal rings or discs

that overlap each other.

THE GEAR DIFFERENTIAL

A gear differential is a mechanism that is capable of

adding and subtracting mechanically. To be more

precise, we should say that it adds the total revolutions

of two shafts. It also subtracts the total revolutions of

one shaft from the total revolutions of another

shaft—and delivers the answer by a third shaft. The gear

differential will continuously and accurately add or

subtract any number of revolutions. It will produce a

continuous series of answers as the inputs change.

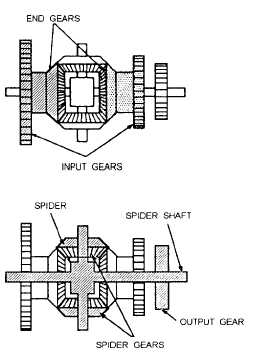

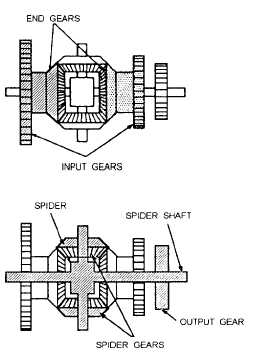

Figure 11-8 is a cutaway drawing of a bevel gear

differential showing all of its parts and how they relate

to each other. Grouped around the center of the

mechanism are four bevel gears meshed together. The

two bevel gears on either side are “end gears.” The two

bevel gears above and below are “spider gears.” The

long shaft running through the end gears and the three

spur gears is the “spider shaft.” The short shaft running

through the spider gears together with the spider gears

themselves make up the “spider.”

Each spider gear and end gear is bearing-mounted

on its shaft and is free to rotate. The spider shaft connects

Figure 11-10.-The differential. End gears and spider

arrangement.

with the spider cross shaft at the center block where they

intersect. The ends of the spider shaft are secured in

flanges or hangers. The spider cross shaft and the spider

shaft are also bearing-mounted and are free to rotate on

their axis. Therefore, since the two shafts are rigidly

connected, the spider (consisting of the spider cross

shaft and the spider gears) must tumble, or spin, on the

axis of the spider shaft.

The three spur gears, shown in figure 11-8, are used

to connect the two end gears and the spider shaft to other

mechanisms. They may be of any convenient size. Each

of the two input spur gears is attached to an end gear. An

input gear and an end gear together are called a “side”

of a differential. The third spur gear is the output gear,

as designated in figure 11-8. This is the only gear pinned

to the spider shaft. All the other differential gears, both

bevel and spur, are bearing-mounted.

Figure 11-9 is an exploded view of a gear

differential showing each of its individual parts. Figure

11-10 is a schematic sketch showing the relationship of

the principle parts. For the present we will assume that

the two sides of the gear system are the inputs and the

gear on the spider shaft is the output. Later we will show

that any of these three gears can be either an input or an

output.

11-7