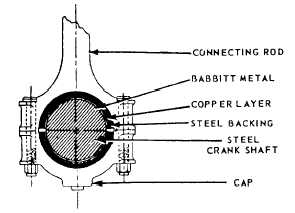

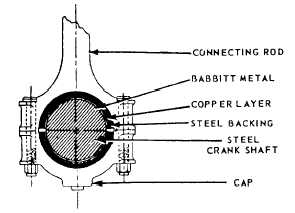

Figure 11-1.-Babbitt-lined bearing in which steel shaft revolves.

clamped or screwed around the shaft (fig. 11-1). We also

call it a laminated sleeve bearing.

Under favorable conditions the friction in journal

bearings is remarkably small. However, when the

rubbing speed of a journal bearing is very low or

extremely high, the friction loss may become excessive.

A good example is the railroad car. Railroad cars are

now being fitted with roller bearings to eliminate the

“hot box” troubles associated with journal bearings.

Heavy-duty bearings have oil circulated around and

through them. Some have an additional cooling system

that circulates water around the bearing. Although

revolving the steel shaft against babbitt metal produces

less friction (and less heat and wear) than steel against

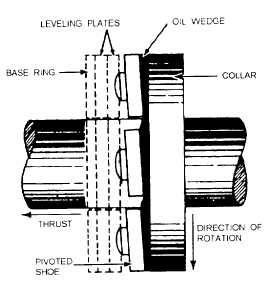

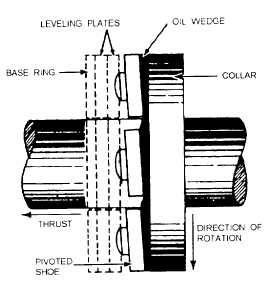

Figure 11-3.-Diagrammatic arrangement of a Kingsbury

thrust bearing, showing oil film.

steel, keeping the parts cool is still a problem. The same

care and lubrication needed to prevent a burned out

bearing on your car is needed on all Navy equipment,

only more so. Many lives depend on the continued

operation of Navy equipment.

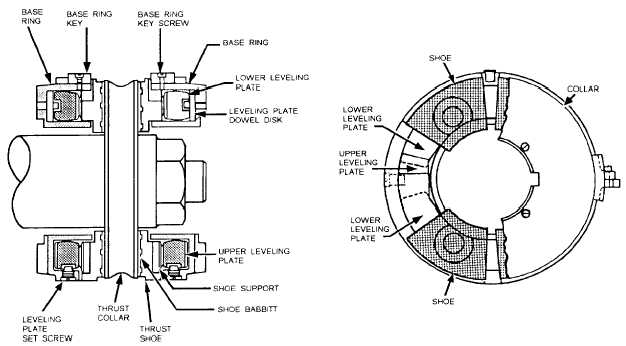

Thrust Bearings

Thrust bearings are used on rotating shafts, such as

those supporting bevel gears, worm gears, propellers,

and fans. They resist axial thrust or force and limit axial

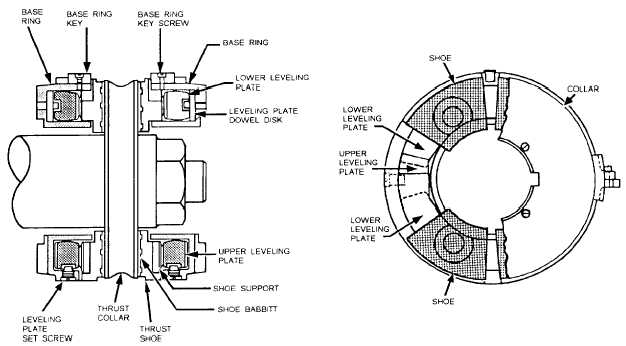

Figure 11-2.-Kingsbury pivoted-shoe thrust bearing.

11-2