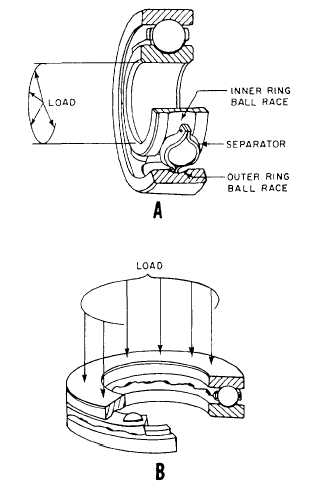

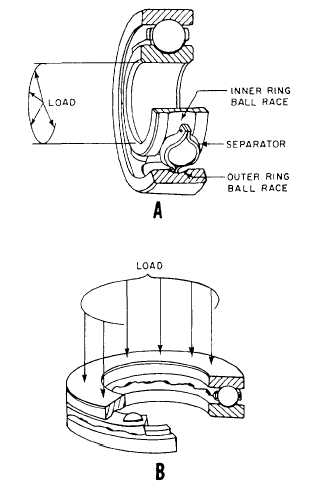

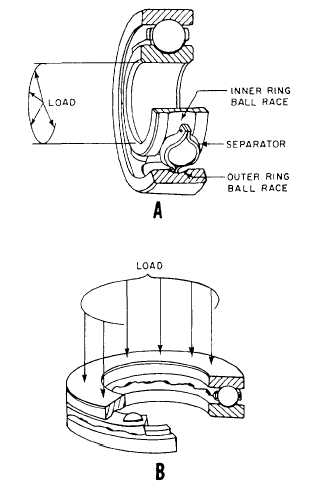

Figure 11-5.-Ball bearings. A.

Radial type; B. Thrust type. 4.

5. 6.

7. Self-aligning

roller bearings with a spherical outer

raceway Self-aligning roller bearings

with a spherical inner raceway

Ball thrust bearings

Needle roller bearings Roller

bearing assemblies are usually easy to

disassemble for inspection, cleaning, and replacement

of parts. Ball bearings are assembled by the manu-

facturer and are installed, or replaced, as a

unit. Sometimes maintenance

publications refer to roller and

ball bearings as either trust or radial bearings. The

difference between the two depends on the angle of

intersection between the direction of the load

and the plane of rotation of the

bearing. Figure 11-5, A, shows

a radial ball bearing assembly.

The load shown is pressing outward along the

radius of the shaft. Now suppose a strong thrust were to

be exerted on the right end of the shaft in an effort

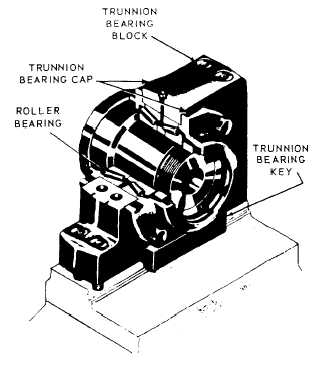

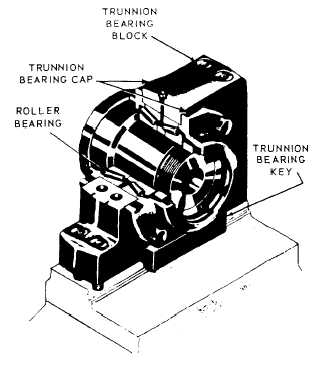

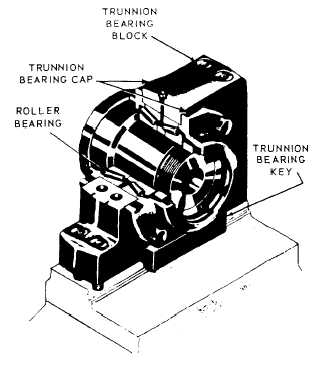

to Figure

11-6.-Radial-thrust roller bearing.

move it to the left. You would find that the radial bearing

is not designed to support this axial thrust. Even

putting a shoulder between the load and

the inner race wouldnt support it;

instead, the bearings would pop out of their

races. Supporting a thrust on the

right end of the shaft would require

the thrust bearing arrangement of the

braces shown in figure 11-5, B. A shoulder under the

lower race and another between the load and the upper

race would handle any axial load up to the design

limit of the bearing.

Sometimes bearings are designed to support both

thrust and radial loads. This explains the use of the

term radial thrust bearings. The

tapered roller bearing in figure 11-6

is an example of a radial-thrust roller

bearing.

Antifriction bearings require smaller housings than

other bearings of the same load capacity and can

operate at higher speeds.

SPRINGS

Springs are elastic bodies (generally metal) that can

be twisted, pulled, or stretched by some force. They

can return to their original shape when

the force is released. All springs

used in naval machinery are made of

metalusually steelthough some are made of

phosphor bronze, brass, or other alloys. A part that

is subject to constant spring thrust or

pressure is said to be

11-4