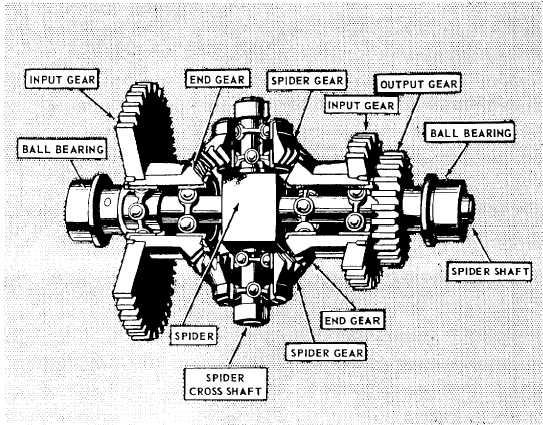

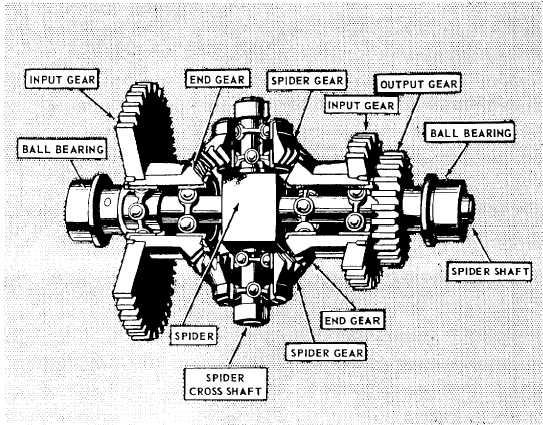

Figure 11-8.-Bevel gear differential.

slightly curved bars, plates, or leaves. They also include

special flat springs (fig. 11-7, A [3]), made from a flat

strip or bar formed into whatever shape or design best

suited for a specific position and purpose.

Spiral Springs

Spiral springs are sometimes called clock, power

(1 1-7, B), or coil springs. A well-known example is a

watch or clock spring; after you wind (tighten) it, it

gradually unwinds and releases power. Although other

names for these springs arc based on good authority, we

call them “spiral” in this text to avoid confusion.

Helical Springs

Helical springs, also often called spiral (fig. 11-7,

D), are probably the most common type of spring. They

may be used in compression (fig. 11-7, D [1]), extension

or tension (fig. 11-7, D [2]), or torsion (fig. 11-7, D [3]).

A spring used in compression tends to shorten in action,

while a tension spring lengthens in action. Torsion

springs, which transmit a twist instead of a direct pull,

operate by a coiling or an uncoiling action.

In addition to straight helical springs, cone,

double-cone, keg, and volute springs are classified as

helical. These types of springs are usually used in

compression. A cone spring (11-7, D [4]), often called a

valve spring because it is frequently used in valves, is

formed by wire being wound on a tapered mandrel

instead of a straight one. A double cone spring (not

illustrated) consists of two cones joined at the small

ends, and a keg spring (not illustrated) consists of two

cone springs joined at their large ends.

Volute springs (fig. 11-7, D [5]) are conical springs

made from a flat bar that is wound so that each coil

partially overlaps the adjacent one. The width (and

thickness) of the material gives it great strength or

resistance.

You can press a conical spring flat so that it requires

little space, and it is not likely to buckle sidewise.

11-6