Figure 9-6.—Knurling and threading toolholders.

This arrangement permits feeding the tool to the

work at any angle (determined by the angular setting of

the swivel section). The graduated collars on the

crossfeed and compound rest feed screws read in

thousandths of an inch for fine adjustment in regulating

the depth of cut.

Accessories and Attachments

Accessories are the tools and equipment used in

routine lathe machining operations. Attachments are

special fixtures that may be mounted on the lathe to

expand the use of the lathe to include taper cutting,

milling, and grinding. Some of the common accessories

and attachments are described in the following

paragraphs.

TOOL POST.—The sole purpose of the tool post is

to provide a rigid support for the tool. It is mounted in

the T-slot of the compound rest. A forged tool or a

toolholder is inserted in the slot in the tool post. By

tightening a setscrew, you will firmly clamp the whole

unit in place with the tool in the desired position.

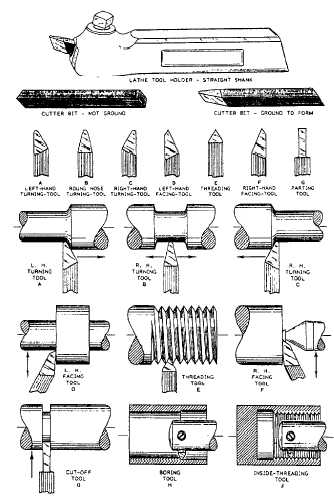

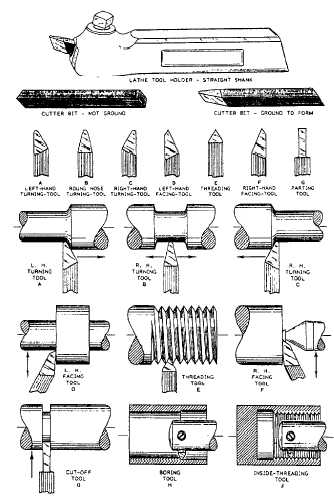

TOOLHOLDERS—Some

of

the

common

toolholders used in lathe work are illustrated in figure

9-5. Notice the angles at which the tool bits are set in the

various holders. These angles must be considered with

respect to the angles ground on the tools and the angle

that the toolholder is set with respect to the axis of the

work.

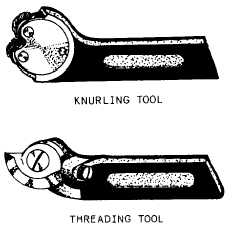

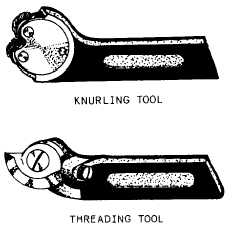

Two types of toolholders that differ slightly from the

common toolholders are those used for threading and

knurling. (See fig. 9-6.)

The threading toolholder has a formed cutter which

needs to be ground only on the top surface for

sharpening. Since the thread form is accurately shaped

Figure 9-7.—Lathe tools and their applications.

over a large arc of the tool, as the surface is worn away

by grinding, the cutter can be rotated to the correct

position and secured by the setscrew.

A knurling toolholder carries two knurled rollers

which impress their patterns on the work as it revolves.

The purpose of the knurling tool is to provide a

roughened surface on round metal parts, such as knobs,

to give a better grip in handling. The knurled rollers

come in a variety of patterns.

ENGINE LATHE TOOLS.—Figure 9-7 shows the

most popular shapes of ground lathe cutter bits and their

applications. In the following paragraphs we will

discuss each of the types shown.

Left-Hand Turning Tool.—This tool is ground for

machining work when it is fed from left to right, as

indicated in figure 9-7, view A. The cutting edge is on

the right side of the tool, and the top of the tool slopes

down away from the cutting edge.

9-5