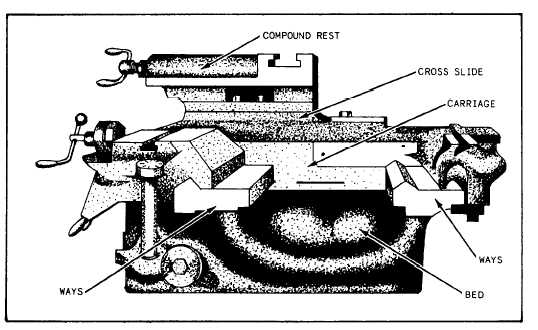

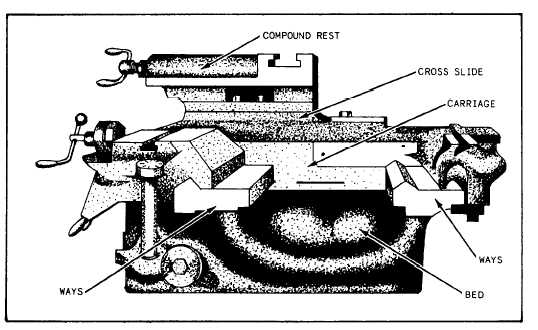

Figure 9-3.—Side view of a carriage mounted on a bed.

machined. However, the tailstock can also be used to

hold tapered shank drills, reamers, and drill chucks. It

can be moved on the ways along the length of the bed

and can be clamped in the desired position by tightening

the tailstock clamping nut. This movement allows for

the turning of different lengths of work. The tailstock

can be adjusted laterally (front to back) to cut a taper by

loosening the clamping screws at the bottom of the

tailstock. (see fig. 9-1.)

Before you insert a dead center, drill, or reamer,

carefully clean the tapered shank and wipe out the

tapered hole of the tailstock spindle. When you hold

drills or reamers in the tapered hole of the spindle, be

sure they are tight enough so they will not revolve. If

you allow them to revolve, they will score the tapered

hole and destroy its accuracy.

Carriage

The carriage is the movable support for the

crossfeed slide and the compound rest. The compound

rest carries the cutting tool in the tool post. Figure 9-3

shows how the carriage travels along the bed over which

it slides on the outboard ways.

The carriage has T-slots or tapped holes to use for

clamping work for boring or milling. When the carriage

is used for boring and milling operations, carriage

movement feeds the work to the cutting tool, which is

rotated by the headstock spindle.

You can lock the carriage in any position on the bed

by tightening the carriage clamp screw. But you do this

only when you do such work as facing or parting-off,

for which longitudinal feed is not required. Normally

the carriage clamp is kept in the released position.

Always move the carriage by hand to be sure it is free

before you engage its automatic feed.

Apron

The apron is attached to the front of the carriage and

contains the mechanism that controls the movement of

the carriage and the crossslide.

Feed Rod

The feed rod transmits power to the apron to drive

the longitudinal feed and crossfeed mechanisms. The

feed rod is driven by the spindle through a train of gears.

The ratio of feed rod speed to spindle speed can be varied

by using change gears to produce various rates of feed.

9-3