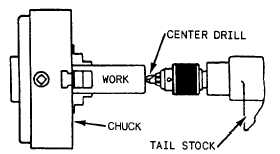

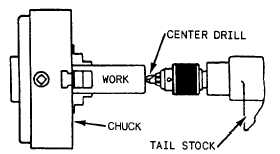

Figure 9-21.—Drilling a center hole.

9-20 show the correct overhang for the tool bit and the

holder.

The point of the tool must be correctly positioned

on the work Place the cutting edge. slightly above the

center for straight turning of steel and cast iron and

exactly on the center for all other work To set the tool

at the height desired, raise or lower the point of the tool

by moving the wedge in or out of the tool post ring. By

placing the point opposite the tailstock center point, you

can adjust the setting accurately.

HOLDING THE WORK

You cannot perform accurate work if the workpiece

is improperly mounted. The requirements for proper

mounting are as follows:

1.

2.

3.

4.

The work center line must be accurately

centered along the axis of the lathe spindle.

The work must be held rigidly while being

turned.

The work must NOT be sprung out of shape by

the holding device.

The work must be adequately supported against

any sagging caused by its own weight and

against springing caused by the action of the

cutting tool.

There are four general methods of holding work in

the lathe: (1) between centers, (2) on a mandrel, (3) in a

chuck, and (4) on a faceplate. Work may also be clamped

to the carriage for boring and milling, in which case the

boring bar or milling cutter is held and driven by the

headstock spindle.

Other methods of holding work to suit special

conditions are (1) one end on the live center or in a chuck

and the other end supported in a center rest, and (2) one

end in a chuck and the other end on the dead center.

Holding Work Between Centers

To machine a workpiece between centers, drill

center holes in each end to receive the lathe centers.

Secure a lathe dog to the workpiece. Then mount

the work between the live and dead centers of the

lathe.

CENTERING THE WORK.—To center round

stock where the ends are to be turned and must be

concentric with the unturned body, mount the work on

the head spindle in a universal chuck or a draw-in collet

chuck If the work is long and too large to pass through

the spindle, use a center rest to support one end. Mount

a center drill in a drill chuck in the tailstock spindle and

feed it to the work by turning the tailstock handwheel

(fig. 9-21).

For center drilling a workpiece, the combined

drill and countersink is the most practical tool.

These combined drills and countersinks vary in

size and the drill points also vary. Sometimes a drill

point on one end will be 1/8 inch in diameter, and

the drill point on the opposite end will be 3/16 inch

in diameter. The angle of the center drill must

always be 60° so that the countersunk hole will fit

the angle of the lathe center point.

If a center drill is not available, center the work

with a small twist drill. Let the drill enter the work

a sufficient distance on each end; then follow with

a 60° countersink.

In center drilling, use a drop or two of oil on the

drill. Feed the drill slowly and carefully to prevent

breaking the tip. Take extreme care when the work is

heavy, because you will be less able to “feel” the

proper feed of the work on the center drill.

If the center drill breaks during countersinking and

part of the broken drill remains in the work, you must

remove this part. Sometimes you can drive the broken

piece out by a chisel or by jarring it loose, but it may

stick so hard that you cannot remove it this way. Then

you must anneal the broken part of the drill and drill it

out.

We cannot overemphasize the importance of

proper center holes in the work and a correct angle

on the point of the lathe centers. To do an accurate

job between centers on the lathe, you must ensure

that the center-drilled holes are the proper size and

depth and that the points of the lathe centers are

true and accurate.

9-13