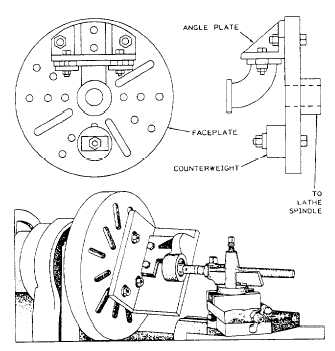

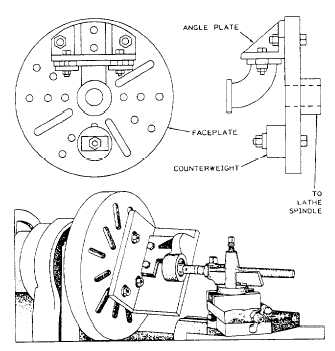

Figure 9-24.—Work clamped to an angle plate.

angle, as shown in figure 9-24. Note the counterweight

added for balance.

For work to be mounted accurately on a faceplate,

the surface of the work in contact with the faceplate must

be accurately faced. It is good practice to place a piece

of paper between the work and the faceplate to prevent

slipping.

Before you clamp the work securely, move it about

on the surface of the faceplate until the point to be

machined is centered accurately with the axis of the

lathe. Suppose you wish to bore a hole, the center of

which has been laid out and marked with a prick punch.

First, clamp the work to the approximate position on the

faceplate. Slide the tailstock up until the dead center just

touches the work. (NOTE: The dead center should have

a sharp, true point.) Now revolve the work slowly; if

the work is off center, the point will scribe a circle on

the work. If the work is on center, the point of the dead

center will coincide with the prick punch mark.

Using the Center Rest and Follower Rest

Place the center rest on the ways where it will give

the greatest support to the workpiece. This is usually at

about the middle of its length.

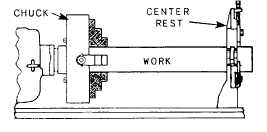

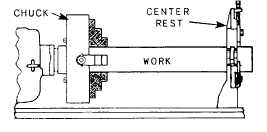

Figure 9-25.—Work mounted in a chuck and center rest.

Ensure that the jaws of the center rest are adjusted

to support the work while allowing it to turn freely.

Figure 9-25 shows how a chuck and center rest are used

for machining the end of a workpiece.

The follower rest differs from the center rest in that

it moves with the carriage and provides support against

the forces of the cut only. Set the tool to the diameter

selected, and turn a “spot” about 5/8 to 3/4 inch wide.

Then adjust the follower rest jaws to the finished

diameter to follow the tool along the entire length to be

turned.

Use a thick oil on the center rest and follower rest

to prevent “seizing” and scoring of the workpiece.

Check the jaws frequently to see that they do not become

hot. The jaws may expand slightly if they get hot,

pushing the work out of alignment (when using the

follower rest) or binding (when using the center rest).

Holding Work in a Draw-In Collet Chuck

The draw-in collet chuck is used for very fine,

accurate work of small diameter. Long work can be

passed through the hollow drawbar. Short work can be

placed directly into the collet from the front. The collet

is tightened on the work by rotating the drawbar to the

right; this draws the collet into the tapered closing

sleeve. The opposite operation releases the collet.

Accurate results are obtained when the diameter of

the work is exactly the same size as the dimension

stamped on the collet. In some cases, the diameter may

vary as much as 0.002 inch; that is, the work may be

0.001 inch smaller or larger than the collet size. If the

work diameter varies more than this, it will impair the

accuracy and efficiency of the collet. That is why a

separate collet should be used for each small variation

or work diameter, especially if precision is desired.

9-16