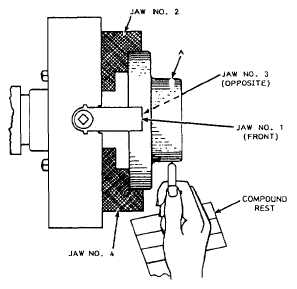

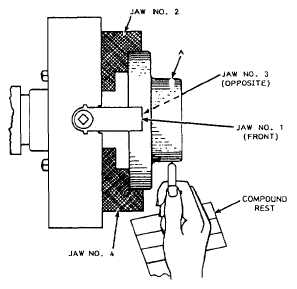

Figure 9-23.—Work mounted in a four-jaw chuck.

rings, put each jaw the same distance from the

outside edge of the body of the chuck.

2. Fasten the work in the chuck by turning the

adjusting screw on jaw 1 and then on jaw 3, a

pair of jaws which are opposite each other. Next,

tighten jaws 2 and 4.

3. At this stage the work should be held in the

jaws just tightly enough so it will not fall out

of the chuck while you turn it.

4. Revolve the spindle slowly by hand and, with

a piece of chalk, mark the high spot (A in fig.

9-23) on the work while it is revolving. Steady

your hand on the tool post while holding the

chalk.

5. Stop the spindle. Locate the high spot on the

work and move the high spot toward the center

of the chuck by releasing the jaw opposite the

chalk mark and tightening the one nearest the

mark

6. Sometimes the high spot on the work will be

located between adjacent jaws. In that case,

loosen the two opposite jaws and tighten the

jaws adjacent to the high spot.

THREE-JAW UNIVERSAL CHUCK.—The

three-jaw universal or scroll chuck is made so that

all jaws move at the same time. A universal chuck

will center almost exactly at the first clamping, but

after a long period of use may develop inaccuracies

of up to 0.010 inch in centering the work. You can

usually correct the inaccuracy by inserting a piece

of paper or thin shim stock between the jaw and the

work on the high side.

When you chuck thin sections, be careful not to

clamp the work too tightly because the work will distort.

If you machine distorted work, the finished work will

have as many high spots as there are jaws, and the turned

surface will not be true.

Care of Chucks

To preserve the accuracy of a chuck, handle it

carefully and keep it clean and free from grit. NEVER

force a chuck jaw by using a pipe as an extension on the

chuck wrench.

Before mounting a chuck, remove the live center

and fill the hole with a rag to prevent chips and dirt from

getting into the tapered hole of the spindle.

Clean and oil the threads of the chuck and the

spindle nose. Dirt or chips on the threads will not

allow the chuck to run true when it is screwed up

to the shoulder. Screw the chuck on carefully,

tightening it just enough to make it difficult to

remove. Never use mechanical power to install a

chuck.

To remove a chuck, place a spanner wrench on the

collar of the chuck and strike a smart blow on the handle

of the wrench with your hand. When you mount or

remove a heavy chuck, lay a board across the bed ways

to protect them; the board will support the chuck as you

put it on or take it off.

The comments on mounting and removing chucks

also apply to faceplates.

Holding Work on a Faceplate

A faceplate is used for mounting work that cannot

be chucked or turned between centers because of its size

or shape.

Work is secured to the faceplate by bolts, clamps, or

any suitable clamping means. The holes and slots in the

faceplate are used for anchoring the holding bolts. Angle

plates may be used to position the work at the desired

9-15