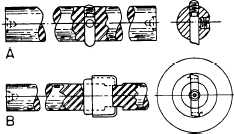

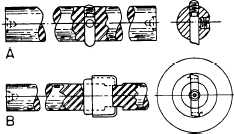

Figure 9-30.–Boring bars.

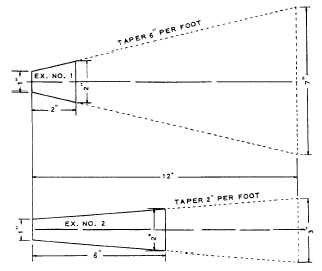

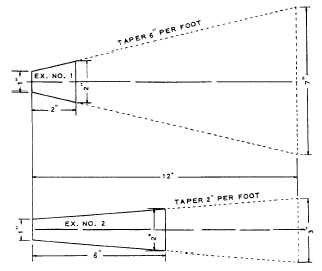

Figure 9-31.–Tapers.

of large diameter. The head is fitted with a fly cutter

similar to the one shown in view A of figure 9-30. The

setscrew with the tapered point adjusts the cutter to the

work

TAPERS

Although you will probably have little need to

machine tapers, we have provided the following

explanation for your basic knowledge.

A taper is the gradual decrease in the diameter of a

piece of work toward one end. The amount of taper in

any given length of work is found by subtracting the size

of the small end from the size of the large end. Taper is

usually expressed as the amount of taper per foot of

length or taper per inch of length. We will take two

examples. (See fig. 9-31.)

Example l.–Find the taper per foot of a piece of

work 2 inches long. The diameter of the small end is 1

inch; the diameter of the large end is 2 inches.

The amount of taper is 2 inches minus 1 inch, which

equals 1 inch. The length of the taper is given as 2 inches.

Therefore, the taper is 1 inch in 2 inches of length. In 12

inches of length the taper is 6 inches. (See fig. 9-31.)

Example 2.–Find the taper per foot of a piece 6

inches long. The diameter of the small end is 1 inch; the

diameter of the large end is 2 inches.

The amount of taper is the same as in example 1,

that is, 1 inch. However, the length of this taper is 6

inches; hence the taper per foot is 1 inch times 12/6,

which equals 2 inches per foot (fig. 9-31).

SAFETY PRECAUTIONS

In machining operations, always keep safety in

mind, no matter how important the job is or how

well you know the machine you are operating.

Listed here are some safety precautions that you

MUST follow:

1. Before starting any lathe operations, always

prepare yourself by rolling up your shirt sleeves and

removing your watch, rings, and other jewelry that

might become caught while you operate the machine.

2. Wear goggles or an approved face shield at all

times whenever you operate a lathe or when you are near

a lathe that is being operated.

3. Be sure the work area is clear of obstructions that

you might fall or trip over.

4. Keep the deck area around your machine clear

of oil or grease to prevent the possibility of slipping or

falling into the machine.

5. Always use assistance when handling large

workpieces or large chucks.

6. NEVER remove chips with your bare hands.

Use a stick or brush, and always stop the machine.

7. Always secure power to the machine when you

take measurements or make adjustments to the chuck.

8. Be attentive, not only to the operation of your

machine, but also to events going on around it. NEVER

permit skylarking in the area.

9. Should it become necessary to operate the lathe

while the ship is underway, be especially safety

conscious. (Machines should be operated ONLY in

relatively calm seas.)

9-19