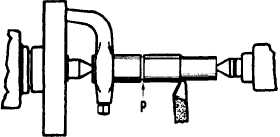

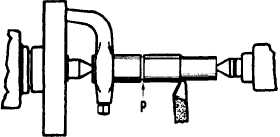

Figure 9-29.—Machining to a shoulder.

occurs during machining to change the position of the

tool, it will not dig into the work, but rather will move

in the direction of the arrow-away from the work

Finish Turning

When you have rough turned the work to within

about 1/32 inch of the finished size, take a finishing cut.

A fine feed, the proper lubricant, and, above all, a

keen-edged tool are necessary to produce a smooth

finish. Measure carefully to be sure you are machining

the work to the proper dimension. Stop the lathe when

you take measurements.

If you must finish the work to close tolerances, be

sure the work is not hot when you take the finish cut. If

you turn the workpiece to exact size when it is hot, it

will be undersize when it has cooled.

Perhaps the most difficult operation for a beginner

in machine work is to make accurate measurements. So

much depends on the accuracy of the work that you

should make every effort to become proficient in the use

of measuring instruments. You will develop a certain

“feel” in the application of micrometers through

experience alone; do not be discouraged if your first

efforts do not produce perfect results. Practice taking

micrometer measurements on pieces of known

dimensions. You will acquire skill if you are persistent.

Turning to a Shoulder

Machining to a shoulder is often done by locating

the shoulder with a parting tool. Insert the parting tool

about 1/32 inch from the shoulder line toward the small

diameter end of the work Cut to a depth 1/32 inch larger

than the small diameter of the work. Then machine the

stock by taking heavy chips up to the shoulder. This

procedure eliminates detailed measuring and speeds up

production.

Figure 9-29 illustrates this method of shouldering.

A parting tool has been used at P and the turning tool is

taking a chip. It will be unnecessary to waste any time

in taking measurements. You can devote your time to

rough machining until the necessary stock is removed.

Then you can take a finishing cut to accurate

measurement.

Boring

Boring is the machining of holes or any interior

cylindrical surface. The piece to be bored must have a

drilled or cored hole, and the hole must be large enough

to insert the tool. The boring process merely enlarges the

hole to the desired size or shape. The advantage of

boring is that a true round hole is obtained, and two or

more holes of the same or different diameters may be

bored at one setting, thus ensuring absolute alignment

of the axis of the holes.

Work to be bored may be held in a chuck, bolted to

the faceplate, or bolted to the carriage. Long pieces must

be supported at the free end in a center rest.

When the boring tool is fed into the hole of work

being rotated on a chuck or faceplate, the process is

called single point boring. It is the same as turning

except that the cutting chip is taken from the inside. The

cutting edge of the boring tool resembles that of a

turning tool. Boring tools may be the solid forged type

or the inserted cutter bit type.

When the work to be bored is clamped to the top of

the carriage, a boring bar is held between centers and

driven by a dog. The work is fed to the tool by the

automatic longitudinal feed of the carriage. Three types

of boring bars are shown in figure 9-30. Note the center

holes at the ends to fit the lathe centers.

Figure 9-30, view A, shows a boring bar fitted with

a fly cutter held by a headless setscrew. The other

setscrew, bearing on the end of the cutter, is for adjusting

the cutter to the work

Figure 9-30, view B, shows a boring bar fitted with

a two-edged cutter held by a taper key. This is more of

a finishing or sizing cutter, as it cuts on both sides and

is used for production work.

The boring bar shown in figure 9-30, view C, is

fitted with a cast-iron head to adapt it for boring work

9-18