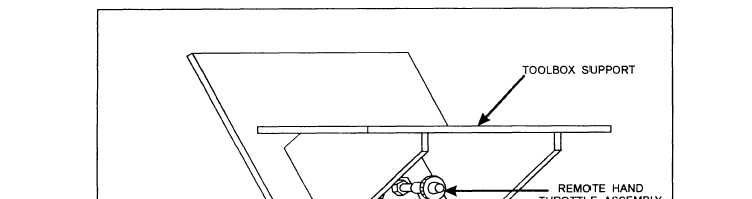

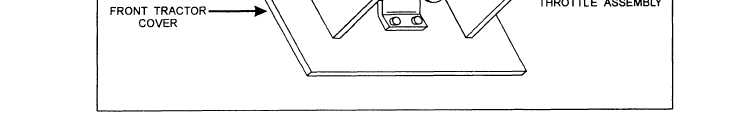

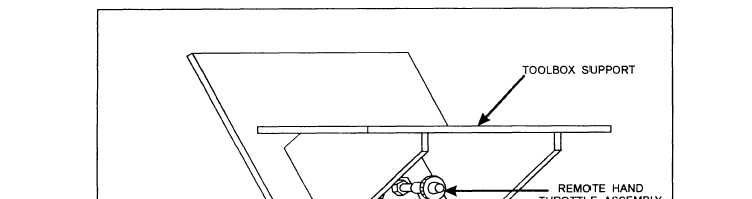

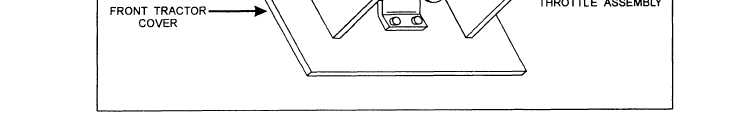

Figure 9-40.—Remote hand throttle assembly.

4. The loader is equipped with a remote hand

throttle assembly (fig. 9-40) located on the front cover

of the loader, which is behind the backhoe operator’s

seat. The hand throttle is preset to the backhoe

specifications to deliver the proper amount of hydraulic

oil flow for backhoe operations. The speed of the engine

determines the volume of hydraulic oil delivered to the

backhoe and the speed of the cylinder movements.

Because of this, you should set the engine at a low speed

until you are familiar with the control lever pattern.

NOTE: The backhoe is designed to operate effi-

ciently at a preset gallons per minute flow of hydraulic

fluid. Setting the engine throttle in excess of that set for

backhoe operations creates excessive hydraulic

temperatures and pressures that can damage hydraulic

and structural components.

5. Lower the backhoe stabilizer legs to fix the

backhoe in position.

6. Warm up the backhoe hydraulic system by

extending and retracting each hydraulic cylinder piston

rod several times to circulate warm oil through the

hydraulic system. When the backhoe hoses feel warm

when touched, the backhoe is ready for operation.

WARNING

Before performing maintenance on the

backhoe, you must extend the dipper stick fully

and set the bucket and stabilizer on the ground.

Shut down the engine, and actuate all of the

control levers back and forth to relieve the

hydraulic pressure in the system.

Loader Backhoe

The loader backhoe tractor (fig. 9-41) is equipped

with a 1.3-cubic-yard bucket mounted on the front and

the backhoe mounted on the rear.

The loader is equipped with a four-speed transaxle

that permits the gears to be shifted from first or second

to third or fourth and back again to third without

stopping. When shifting gears, always make sure the

engine speed remains in the green area of the

tachometer.

The loader also has a differential lock that gives

equal power to both rear wheels when the machine is

stuck or before the loader is operated through a soft or

muddy area. When the loader is stuck, the differential

lock is actuated as follows:

1.

2.

3.

4.

5.

Make sure the rear wheels are not turning.

Push down the clutch cutout pedal (fig. 9-42).

Push down the differential lock pedal.

Release the clutch cutout pedal.

Increase the engine speed and release the

differential lock pedal.

NOTE: The differential lock releases automatically

when the load is removed.

9-16