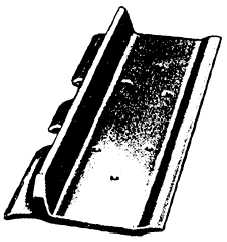

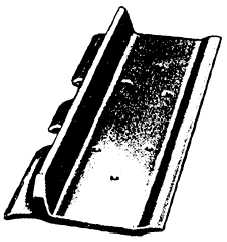

Figure 11-6.-Standard grouser shoe.

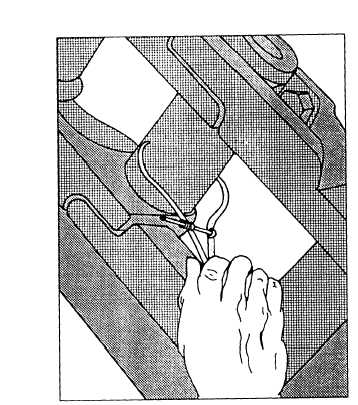

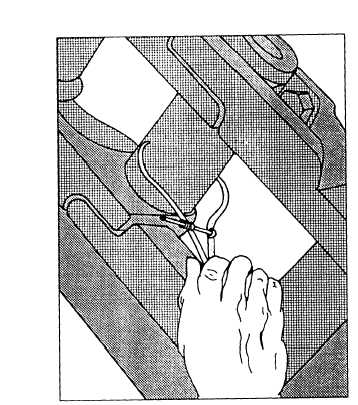

Figure 11-4.—Bushing wear measurement.

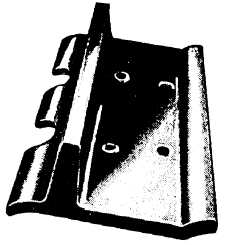

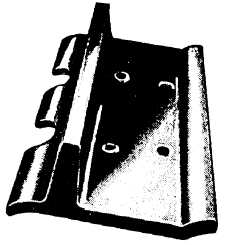

Figure 11-7.—Extreme service track shoe.

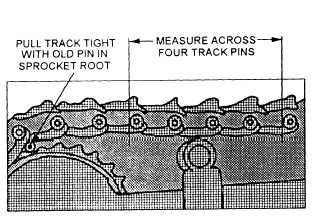

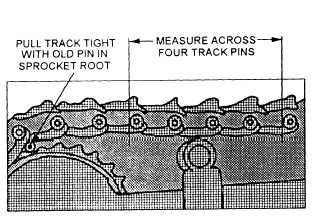

Figure 11-5.—Track pitch measurement.

track pitch with a ruler or tape measure after tightening

the track to remove any slack, as shown in figure 11-5.

TRACK SHOES.— The most common track shoe

is the grouser shoe, as shown in figure 11-6. This shoe

is standard on crawler-mounted dozers. The extreme

service track shoe shown in figure 11-7 is equipped on

crawler-mounted dozers that operate primarily in rocky

locations, such as rock quarries and coral beaches.

Notice the grouser, or raised portion of the shoe, is

heavier than the one on the standard grouser shoe.

NOTE: The grouser absorbs most of the wear and

its condition can indicate when a track needs replace-

ment or overhaul.

Track Frame

The track frame serves as a framework and support

for the track assembly, rollers, front idler, recoil spring,

and adjusting mechanism.

TRACK FRAME ROLLERS.— Two types of

track frame rollers are used on tracked equipment: those

located on the lower portion of the track frame, which

support the weight of the dozer, and those mounted

above the track frame, which support the track, as it

passes over the track frame assembly.

11-3