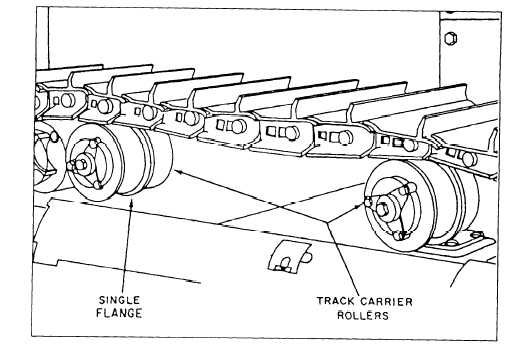

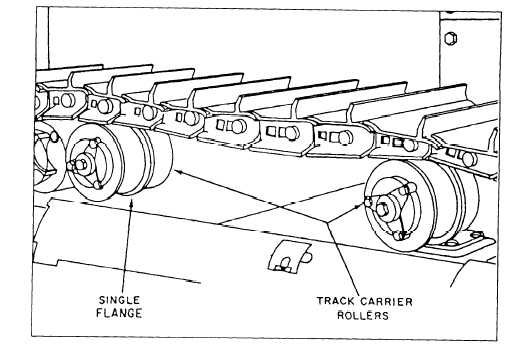

Figure 11-8.-Carrier rollers.

The carrier rollers are mounted on brackets that

extend above the track frame (fig. 11-8). Two of these

rollers are on each side of the dozer. The single flange

on the rollers extends upward between the links of the

track chain and keeps the chain in alignment between

the drive sprocket and the front idler.

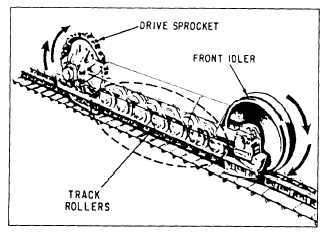

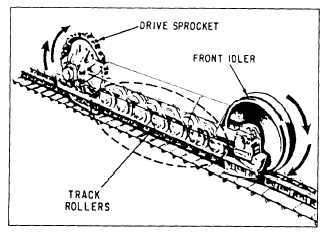

The track rollers support the weight of the dozer and

ensure the track chain is in alignment with the truck

frame, as it passes under the rollers (fig. 11-9). Track

rollers, both single and double flanged, are installed

Figure 11-9.—Track rollers in position in track frame.

alternately. In the normal arrangement, a double-flanged

roller is positioned directly in front of the rear drive

sprocket, followed by a single-flanged roller. The rollers

alternate forward to the front idler.

FRONT IDLER.— The front idler, as shown in

figure 11-9, serves as a guiding support for the track

chain. The idler is spring-loaded and mounted on slides,

or guides, that allow it to move back and forth inside the

track frame, as the dozer passes over uneven ground.

The spring-loading effect causes the idler to maintain

the desired tension regardless of operating conditions.

RECOIL SPRING.— The recoil spring is a large

coil spring placed in the track frame in a way that

enables the spring to absorb shock from the front idler.

The spring is compressed before installation and held in

place by stops or spacers. The track adjusting

mechanism, by pressing against the spring stop,

maintains the desired tension on the track assembly by

holding the idler and yoke in the forward position. The

operation of the coil spring depends on the amount of

tension on the truck.

TRACK ADJUSTING MECHANISM.— The

adjusting mechanism must be extended enough to

remove slack between the front idler and spring. The

adjustment is made either manually (fig. 11-10) or

hydraulically (fig. 11-11). Older model dozers have

mnaually adjustments; whereas, newer dozers are

11-4