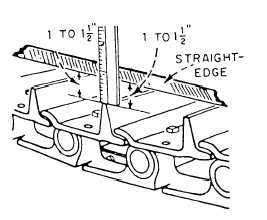

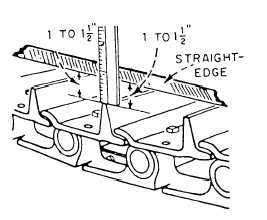

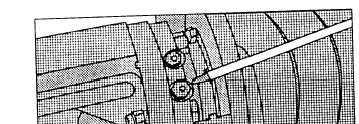

Figure 11-12.—Checking track adjustment.

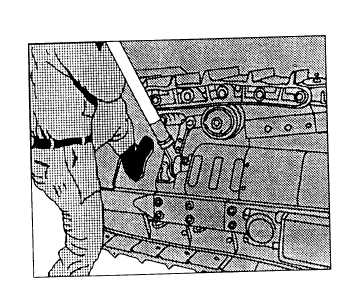

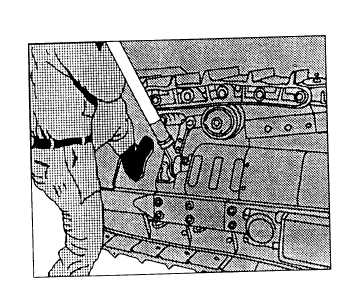

Figure 11-10.-Manual track adjustment.

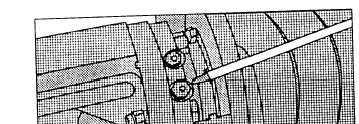

Figure 11-11.-Hydraulic track adjuster.

adjusted hydraulically with a grease gun. Grease is

pumped into the yoke cylinder and extends it until

enough tension is placed on the recoil spring to remove

the slack from the track. Tension is relieved by loosening

the vent screw located next to the adjustment fitting.

NOTE: Do NOT lubricate this fitting when per-

forming daily operator’s maintenance. The track

adjuster fitting should only be greased when the tracks

require adjustment.

Track Adjustment.— To determine proper track

tension, position the dozer on a hard surface. Then place

a straightedge over the front carrier roller and idler with

all slack removed from the rest of the track. The tension

is correct when the measured distance is as shown in

figure 11-12.

Track tension should be suitable for the type of area

you arc working in, such as tighter for rock and looser

for sand and snow. However, if the tracks are adjusted

too tightly, there will be too much friction between the

pins and bushings when the track links swivel, as they

travel around the sprocket and front idler. This friction

causes the pins, bushings, links, sprocket, and idler to

wear rapidly. Friction in a tight track also robs the tractor

of needed horsepower.

Tracks that are too loose fail to stay aligned and tend

to come off when the tractor is turned. As a result, the

idler flanges, roller flanges, and the sides of the sprocket

teeth wear down. A loose track will whip at high speeds,

damaging the carrier rollers and their supports. If loose

enough, the drive sprockets will jump teeth (slide over

the track bushings) when the tractor moves in reverse.

Should this happen, the sprocket and bushings will wear

rapidly.

NOTE: Checking and performing track adjust-

ments arc the opcrator’s responsibility.

Lubrication.

— The track pins and bushings are

hardened and require no lubrication. Many roller idlers

arc equipped with lifetime seals that are filled during

assembly and require no lubrication. However, track

rollers, carrier rollers, and idlers equiped with grease

fittings must be lubricated on a schedule based on the

manufacturer’s specifications.

NOTE: Fittings should be cleaned before lubri-

cating to prevent forcing dirt and grime into the

bearings.

ATTACHMENTS

The most common type of dozer attachment is the

dozer blade, a heavy, rectangular steel blade, that is on

11-5